Introduction to Automation Engineering: Transforming the Industry

As digitization sweeps across industries, Automation Engineering is important in improving operational efficiency and productivity.

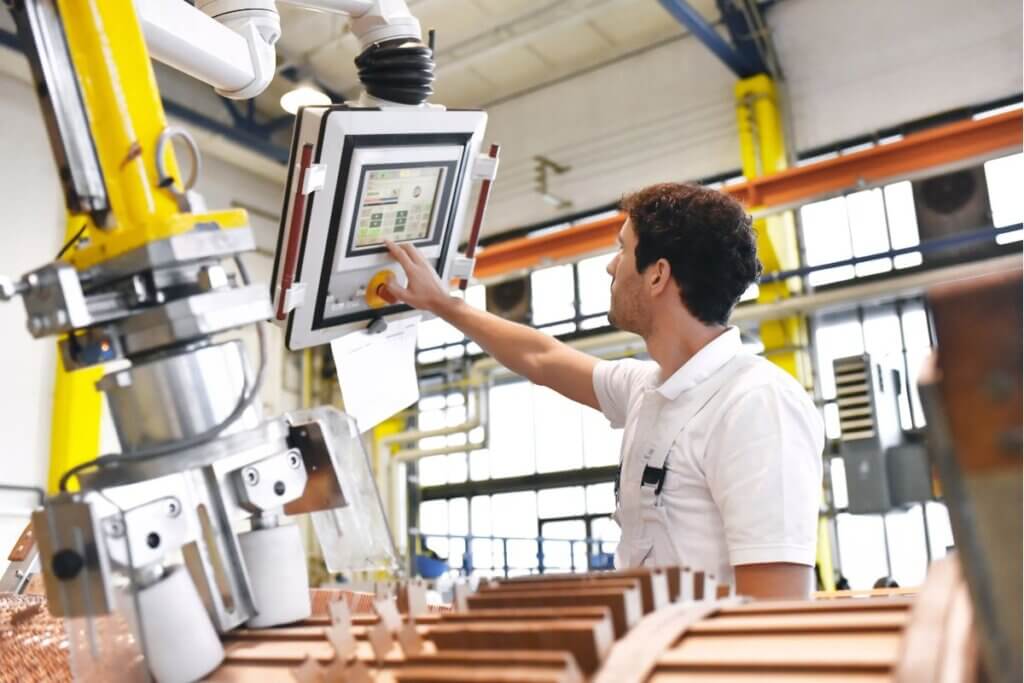

Automation Engineering involves designing and implementing digital or computer systems that imitate or replicate human processes. This reduces manual labor and increases accuracy levels. This discipline is vital as it combines mechanical, electronics, controls, systems, and computer science principles. It transforms myriad sectors, including manufacturing, healthcare, and agriculture.

In the contemporary world, efficiency and innovation are key. Automation Engineering optimizes systems and processes. It also catalyzes technological progress. It reshapes the landscape of various industries. Understanding its importance is essential not only for today but also to be prepared for a tech-driven future.

History of Automation Engineering in a Nutshell

The roots of automation engineering can be traced back to the Industrial Revolution in the 18th century. It is when machinery began to replace manual labor. The first instances and use of automation were predominantly seen in the manufacturing sector. It started with the introduction of steam engines and automated looms. Towards the end of the 19th century, the advent of electricity further propelled the development of automated systems.

The evolution and advancements took a significant leap in the 20th century. It started with the invention of the computer and digital technology. This led to the creation of programmable logic controllers or PLCs and industrial robots. This marked the genesis of automation in modern factories. The later part of the century is the expansion of automation beyond industry to areas such as transportation, healthcare, and domestic appliances.

As we go through the 21st century, the landscape of automation engineering continues to be revolutionized. The emergence of artificial intelligence and machine learning technologies now plays an important role.

Fundamentals of Automation Engineering

Automation Engineering is a specialized engineering branch that designs and implements automated systems. The basic principles of this field are centered around the application of control theory and computer technology. It is to design systems capable of operating with minimal or no human intervention.

The core components include:

- control systems, such as programmable logic controllers (PLCs) and supervisory control and data acquisition (SCADA) systems

- robots

- conveyors

- machine vision systems

These elements are combined to create different types of automation systems. These systems range from simple on-off control loops used in manufacturing operations. Not to mention complex, integrated systems that can control entire production lines or facilities.

Regardless of the system’s complexity, the main goal remains the same: to improve efficiency, safety, and productivity while reducing human intervention and errors.

Role of Automation Engineering in Industry Transformation

Automation engineering is important in transforming various industries. It significantly revolutionizes work processes and boosts productivity. This has led to substantial changes in the manufacturing sector. It minimizes human intervention, reducing errors and making assembly lines more efficient.

Automation reduces the risk of accidents, allows high precision, and saves time, resulting in cost-effectiveness. In the service industry, automation has streamlined operations. This leads to quick service delivery, increased accuracy, and enhanced customer experience. For instance, using chatbots and automated email services has revolutionized customer service.

Furthermore, automation engineering has significantly impacted the agricultural and mining sectors. It has introduced innovations like automated irrigation systems, robotics in harvesting and mining operations, and drones for field surveillance. These advances ensure efficient resource utilization, increased yield, safer work environments, and overall industry growth. It is instrumental in driving industry transformation across different sectors.

Key Benefits of Automation Engineering

Automation Engineering offers numerous key benefits contributing to businesses’ growth and development. Enhancing efficiency and productivity allows industries to streamline their processes. It achieves optimal output levels with the highest precision. This sophisticated technology drastically reduces errors. This ensures consistent and superior product or service quality.

Furthermore, it plays a critical role in boosting profitability. This is possible as automation eliminates the need for manual labor in repetitive tasks. It speeds up the overall production rate and reduces operational costs. It is an invaluable tool for achieving high efficiency, quality, and profitability standards.

Current Trends in Automation Engineering

Automation engineering has brought notable changes to various industries. It has accelerated advancements in productivity, efficiency, and quality. The rise of Artificial Intelligence (AI) and Machine Learning (ML) in automation has considerably enhanced decision-making processes, predictive capabilities, and error reduction, ultimately driving innovation and cost savings.

Meanwhile, the Industrial Internet of Things (IIoT) surge has unprecedentedly connected machines, systems, and devices, allowing real-time data collection, processing, and analysis to streamline operations, improve safety, and increase machine uptime.

Additionally, automation is crucial in breaking down complex information into actionable insights in this era of rapid digital transformation, fostering workflow agility and adaptability. From manufacturing to healthcare, the benefits of automation engineering are profound, reshaping the future of work and paving the way for a more efficient, productive, and innovative global industry landscape.

Case Studies of Successful Automation Engineering Implementation

Several industries have effectively integrated automation engineering to gain a competitive advantage in the global market. For instance, manufacturing has incorporated automation tools to streamline production processes and reduce human errors. It increases efficiency and lower costs. Similarly, the healthcare sector uses automated systems for precision in diagnostics and surgical procedures. This improves patient outcomes. Furthermore, the hospitality industry has successfully used automated systems for bookings and customer service. Enhancing user experience.

These case studies show that the key to successful automation implementation lies in the following:

- understanding the industry’s specific needs

- continuous process monitoring

- incorporating necessary modifications for optimal results.

These insights can guide further initiatives toward successful and sustainable automation implementations.

Future of Automation Engineering

The future of Automation Engineering is bright and promising. Potential developments and innovations are on the horizon. Automation plays a crucial role in shaping the future of work. Replacing manual tasks with automated processes, increasing efficiency, reducing errors, and leading the way toward a new era of productivity.

Moreover, automation could contribute significantly to environmental sustainability by minimizing resource wastage and improving energy efficiency. Innovations like AI-powered automation, Robotics, and Machine Learning are poised to revolutionize industries. Creating new jobs and paving the path for a more sustainable future. Integrating these advanced technologies in automation engineering will transform our lives and the world around us.

Conclusion

In conclusion, the significance of Automation Engineering cannot be overstated. It is an ever-evolving field that revolutionizes various industries, enhancing efficiency, productivity, and accuracy. Its role in the technological world is fundamental as it paves the way for innovative automation solutions transforming businesses’ operations. Looking toward the future, it can be projected that the importance and influence of Automation Engineering will only continue to grow.

Technological advancements, artificial intelligence, and machine learning will continue to expand this field. Hence, with continuous innovation and improvements, the future of Automation Engineering is promising and holds exciting prospects.

Why Choose Automation Ready Panels for your next Automation Engineering Project?

We are known for our high-quality, pre-built, pre-programmed control panels and manufacturing expertise, perfect for your automation engineering needs. Our expertise assures you of our ability to handle the largest and most complex panels quickly and efficiently while including the highest levels of standards and trends in automation engineering.

Considering us for your next automation engineering project gives you the following benefits:

- We are an expert in the field, applying the latest trends and standards.

- We can do your project’s software, hardware, and management aspects.

- Our work is flexible and will show immediate payback for your operations in terms of utility costs, equipment wear, and/or flexibility of automation.

Contact us today at Automation Ready Panels.

-

Large Process Automation: Panelview 5000, ControlLogix 5580

$24,073.00 Select options -

Small Process Automation: Panelview 5000, ControlLogix 5580

$20,321.00 Select options -

Small Process Automation: ControlLogix 5580, UPS Battery Backup, Cellular Modem

$18,999.00 Select options -

Advanced Automation: Panelview 5000, Safety CompactLogix 5380

$10,269.00 Select options