Process Automation Panels: Streamlining Industrial Efficiency

In today’s fast-paced industrial landscape, automation has become the cornerstone of productivity and efficiency. For businesses aiming to reduce downtime, improve reliability, and achieve precision, process automation panels play an integral role. These panels act as the brains behind automated systems, ensuring seamless communication between devices, machinery, and operators.

For organizations in the U.S. seeking high-quality, pre-built PLC panels, Automation Ready Panels offers a solution tailored to your automation needs. This article dives into the importance of process automation panels, their components, benefits, and how companies like Automation Ready Panels are shaping the future of industrial automation.

What Are Process Automation Panels?

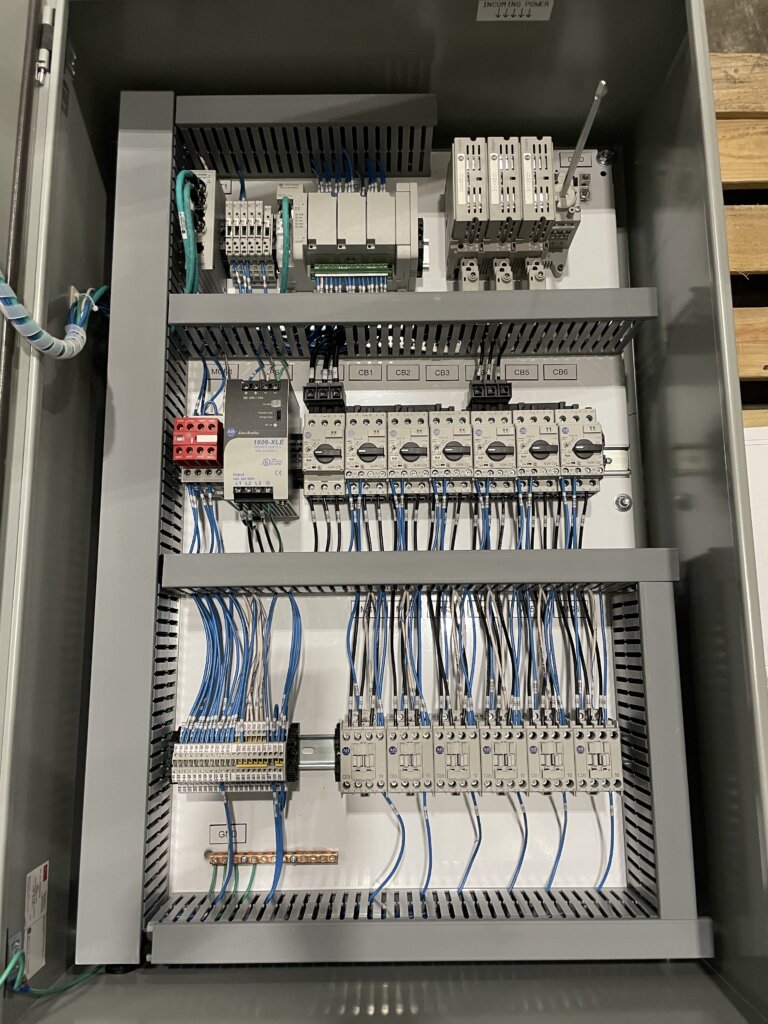

Process automation panels are specialized control systems designed to automate and monitor industrial processes. These panels house programmable logic controllers (PLCs), human-machine interfaces (HMIs), and other essential components to control and optimize operations.

Key Components of Process Automation Panels

- Programmable Logic Controllers (PLCs): Central to automation, PLCs process inputs and control outputs to manage industrial equipment.

- Human-Machine Interfaces (HMIs): Enable operators to interact with the automation system through graphical displays.

- Power Supplies: Provide consistent and reliable energy to the entire system.

- Input/Output Modules (I/O): Facilitate communication between sensors, actuators, and the PLC.

- Communication Modules: Allow the system to integrate with other devices and networks.

Why Invest in Pre-Built Process Automation Panels?

Investing in pre-built process automation panels provides businesses with a strategic edge by combining efficiency, cost savings, and reliability. Here’s a deeper dive into the key benefits:

1. Faster Deployment

Pre-built panels are manufactured and assembled in advance, meaning they are ready for immediate integration. For businesses under tight deadlines or with critical operational needs, pre-built panels eliminate the time-consuming processes of design, testing, and on-site customization. This faster deployment ensures minimal disruptions to production timelines.

2. Cost-Effective Solutions

Custom-designed automation panels often involve higher engineering, design, and assembly costs. Pre-built panels, however, leverage standardized designs that reduce manufacturing complexity and associated expenses. Additionally, the use of modular components in pre-built panels allows for easy replacements or upgrades, further lowering long-term operational costs.

3. Proven Reliability

Each pre-built panel undergoes rigorous testing before shipment to ensure it meets operational requirements. These standardized designs are developed based on industry best practices and common use cases, reducing the risk of faults or malfunctions. For businesses prioritizing uptime and reliability, pre-built solutions offer peace of mind.

4. Simplified Maintenance

Pre-built panels often include detailed documentation, wiring diagrams, and maintenance schedules, making upkeep straightforward. Components are standardized, which simplifies troubleshooting and reduces downtime during repairs or replacements.

5. Scalability for Future Needs

Businesses grow, and so do their operational demands. Pre-built panels are designed with scalability in mind, enabling seamless expansion or upgrades. Whether it’s adding new modules or integrating with advanced technologies, pre-built solutions offer the flexibility to evolve with your operations.

6. Compliance and Certifications

Automation Ready Panels ensures that all their pre-built panels meet stringent industry standards, including UL, CE, and NFPA certifications. By investing in compliant panels, businesses can avoid legal or operational complications, especially in regulated industries.

How Process Automation Panels Improve Industrial Operations

Process automation panels are more than just hardware; they represent a comprehensive solution for enhancing productivity and operational control. Here’s how they transform industrial operations:

1. Reduced Downtime

Automation panels incorporate monitoring and diagnostic tools that detect potential issues early. For instance, sensors connected to the panel can identify equipment wear, overheating, or system anomalies, triggering alerts before a failure occurs. This proactive approach minimizes costly downtime and keeps operations running smoothly.

2. Increased Accuracy and Consistency

Manual processes are prone to human error, leading to inconsistent results. Automation panels, however, execute tasks with precision, ensuring consistent quality across operations. For example, in manufacturing, automation panels can regulate assembly line speeds, manage robotic arms, and monitor product dimensions, guaranteeing uniformity.

3. Energy Efficiency

Industrial facilities are significant energy consumers. Automation panels optimize energy use by monitoring equipment performance and shutting down systems when not in use. For instance, HVAC systems, pumps, and conveyors can be automated to operate only when required, significantly lowering energy bills.

4. Improved Data Collection and Analysis

Modern automation panels are equipped with data logging and analytics capabilities. They gather critical metrics such as machine performance, temperature variations, and operational bottlenecks. This data empowers businesses to make informed decisions, optimize workflows, and predict future needs.

5. Enhanced Safety Standards

Safety is paramount in industrial operations. Automation panels help mitigate risks by monitoring hazardous environments and triggering emergency shutdowns when necessary. For example, panels can integrate with gas detectors or pressure sensors to prevent accidents in oil refineries or chemical plants.

6. Seamless Integration with IoT

Automation panels are increasingly designed to work within the Industrial Internet of Things (IIoT) ecosystem. This enables remote monitoring, real-time adjustments, and predictive maintenance, all from a central dashboard. For example, factory managers can use IoT-enabled panels to oversee global operations from a single location.

Industries That Benefit from Process Automation Panels

Process automation panels are indispensable across a wide range of industries. Let’s explore how specific sectors leverage these solutions:

1. Manufacturing

In manufacturing, efficiency and consistency are critical. Automation panels:

- Manage assembly lines, ensuring smooth operation and minimal downtime.

- Control robotic systems for tasks like welding, painting, or material handling.

- Integrate quality control mechanisms, such as real-time monitoring of product dimensions or defects.

For example, automobile manufacturers rely on automation panels to coordinate robotic arms for precise assembly of car components.

2. Oil and Gas

This sector deals with highly complex and hazardous processes, such as drilling, refining, and transportation. Automation panels:

- Monitor critical variables like pressure, temperature, and flow rates.

- Trigger emergency shutdowns in case of system anomalies.

- Optimize energy consumption during refining or pumping operations.

By leveraging automation panels, oil and gas companies can ensure both operational safety and regulatory compliance.

3. Water Treatment and Utilities

Water treatment plants depend on automation for continuous operation and regulatory compliance. Automation panels:

- Control filtration systems to remove impurities.

- Regulate the flow of water through treatment phases.

- Monitor pH levels, turbidity, and chemical dosing to ensure safe and clean water supply.

For municipal water facilities, these panels are indispensable for maintaining consistent output and meeting EPA standards.

4. Food and Beverage

The food and beverage industry requires strict adherence to hygiene and quality standards. Automation panels:

- Automate mixing, packaging, and labeling processes to maintain consistency.

- Monitor refrigeration and storage systems to ensure food safety.

- Track production data to optimize efficiency and reduce waste.

For example, breweries use automation panels to control fermentation processes, ensuring precise temperatures and timings for consistent flavor profiles.

5. Pharmaceuticals

In pharmaceutical manufacturing, precision and compliance are non-negotiable. Automation panels:

- Control mixing and compounding processes with millisecond accuracy.

- Ensure compliance with FDA regulations through precise monitoring and reporting.

- Facilitate scalability in production to meet increasing demand.

By automating critical processes, pharmaceutical companies can focus on innovation while maintaining safety and quality.

6. Renewable Energy

In solar and wind energy, automation panels:

- Manage power distribution from generation to storage systems.

- Monitor equipment performance to maximize energy output.

- Enable remote monitoring and diagnostics to reduce maintenance costs.

What to Look for in a Process Automation Panel Provider

When selecting a provider for process automation panels, consider these factors:

- Experience and Expertise

Ensure the company specializes in automation and has a proven track record. - Customization Options

While pre-built panels offer convenience, the ability to tweak designs for specific needs is a plus. - Compliance Standards

Ensure products meet safety and regulatory guidelines like UL and CE certifications. - Support Services

Look for providers offering support and ongoing maintenance.

Automation Ready Panels excels in all these areas, providing reliable and efficient pre-built PLC panels across the U.S.

FAQ: Process Automation Panels

Q: What is the lifespan of a process automation panel?

A: With proper maintenance, panels can last 10-15 years or longer. Regular updates ensure compatibility with new technologies.

Q: Are pre-built panels suitable for large-scale operations?

A: Yes, pre-built panels are scalable and can be configured to meet the needs of both small and large industrial setups.

Q: How do I maintain my automation panel?

A: Regularly inspect connections, clean components, and update software to ensure optimal performance.

Why Choose Automation Ready Panels?

Automation Ready Panels simplifies industrial automation with its range of pre-built PLC panels. Here’s why they are a trusted choice:

- U.S.-Based Expertise: With extensive experience in automation, they understand the unique challenges of American industries.

- High-Quality Products: Every panel is rigorously tested for performance and compliance.

- Quick Turnaround: Pre-built solutions mean faster integration and minimized downtime.

- Customer Support: Our team is with you every step of the way.

Conclusion

Process automation panels are the backbone of modern industrial systems, driving efficiency, accuracy, and safety. Companies like Automation Ready Panels make automation accessible with their pre-built PLC panels, tailored to meet the diverse needs of U.S. industries.

Take the first step toward optimizing your operations today. Contact Automation Ready Panels for expert guidance and high-quality automation solutions.

-

Large Process Automation: Panelview 5000, ControlLogix 5580

$24,073.00 Select options -

Small Process Automation: Panelview 5000, ControlLogix 5580

$20,321.00 Select options -

Small Process Automation: ControlLogix 5580, UPS Battery Backup, Cellular Modem

$18,999.00 Select options -

Advanced Automation: Panelview 5000, Safety CompactLogix 5380

$10,269.00 Select options