Be an Expert PLC Programmer: Master Ladder Logic and PLCs

Want to learn PLC programming and become a skilled PLC programmer? This comprehensive guide covers everything you need to know, from the basics of PLCs to advanced programming techniques. Read on to learn the key skills required and get tips for developing proficiency.

Programmable Logic Controllers (PLCs) are essential for industrial automation and control systems. As manufacturing processes become more complex, the demand for competent PLC programmers rises. We’ll explore what’s involved in PLC programming, the languages used, and career paths, and answer frequently asked questions for those looking to become proficient.

Article Outline

- What is a PLC, and What Do PLC Programmers Do?

- Why Become a PLC Programmer?

- What Programming Languages Are Used for PLCs?

- What Skills Are Required to Be a Good PLC Programmer?

- How Do I Learn PLC Programming?

- What Are the Day-to-Day Responsibilities of a PLC Programmer?

- 10 Frequently Asked Interview Questions for PLC Programmers

- Key Takeaways: Skills Needed to Become a Proficient PLC Programmer

What is a PLC, and What do PLC Programmers do?

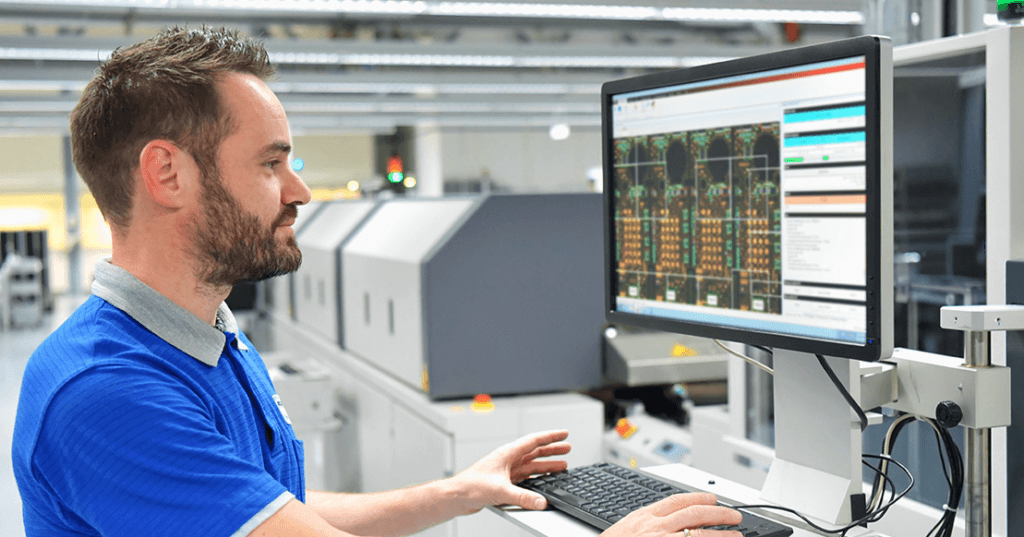

A Programmable Logic Controller is an industrial computer that manages and automates control of manufacturing plant equipment and machinery. PLC systems use ladder logic, a programming language representing circuits, to control electromechanical processes via digital and analog I/O.

PLC programmers design, troubleshoot, optimize, and maintain the code, circuits, and programs that allow PLCs to function. Their expertise ensures reliable, efficient, and automated operation of assembly lines and machinery. Those with advanced skills in PLC programming often help interface complex PLC systems with HMI software and SCADA systems.

Why Become a PLC Programmer?

There are growing career opportunities in the automation industry for skilled PLC programmers as increasing manufacturing complexity drives demand. PLC programming skills command strong salaries, offer job stability, and allow working with cutting-edge automation technologies.

What Programming Languages are Used for PLCs?

While ladder logic diagrams are the most common PLC programming language, most modern PLCs also support:

- Structured Text

- Function Block Diagram

- Sequential Function Chart

In addition, PLC programming software provides an interface to develop, test, and troubleshoot PLC programs on a computer before deploying them. Common programming software used with PLCs includes RSLogix 500, RSLogix 5000, and Codesys.

Learning multiple PLC programming languages and various programming software expands your capabilities working across different PLC hardware and brands in industrial settings.

What Skills Are Required to Be a Good PLC Programmer?

To be a successful PLC programmer requires:

- Solid grasp of digital logic and electrical circuits

- Proficiency in ladder logic and other PLC programming languages

- Understanding of PLC hardware configurations and capabilities

- Knowledge of communication protocols (Ethernet, RS232, etc.)

- Troubleshooting and problem-solving skills

- Analytical capabilities

- Attention to detail

Though a background in electrical engineering or computer programming is helpful, it’s possible to learn PLC programming and develop the required knowledge and skills. PLC programmers often have strong problem-solving and troubleshooting skills gained through hands-on experience.

How Do I Learn PLC Programming?

When starting, free PLC programming software allows for learning ladder logic, FBD, and other programming languages. But it’s key to also get hands-on with actual PLC hardware. Look for affordable beginner’s PLCs and training kits. Connecting real inputs and outputs builds core programming skills faster.

Once comfortable with basic ladder logic elements, shift to programming more complex logic and working with analog signals on more advanced PLCs. At this stage, learning functions like timers, counters, and math blocks tied to real hardware expand capabilities.

As proficiency grows, mastering multiple PLC programming languages used by leading PLC manufacturers becomes important. The goal is to adapt your programming skills seamlessly across the various PLC platforms found in the field.

What Are the Day-to-Day Responsibilities of a PLC Programmer?

Daily, PLC programmers may:

- Collaborate with engineers on automation solutions

- Program new control code and logic for equipment/machinery

- Modify and optimize existing PLC system code

- Perform simulations to test new control programs

- Analyze PLC functionality for faults/defects

- Troubleshoot issues and debug code

- Document all changes to PLC programs

- Remain current on the latest PLC hardware, software, and programming best practices

Strong analytical and troubleshooting skills are essential for PLC programmers since they ensure reliable PLC operation on critical manufacturing lines. They also need the expertise to identify and correct issues with PLC hardware, software, and programming.

Adaptability is vital as they must constantly learn new PLC platforms, automation approaches, and programming techniques throughout their career.

10 Frequently Asked Interview Questions for PLC Programmers

-

What experience do you have programming PLCs?

Recruiters look for candidates with hands-on experience beyond just ladder logic training. Be ready to outline real-world skills.

-

What PLC programming languages are you familiar with?

Highlight broader knowledge beyond just ladder logic. Discuss experience with FBD, SFC, ST, etc.

-

What PLC hardware systems have you worked with?

Show comfort programming various PLC models from Allen-Bradley, Siemens, Omron, Schneider, etc.

-

How would you approach troubleshooting a problem with a PLC system?

Demonstrate a structured troubleshooting approach and sound grasp of key failure points.

-

What steps are involved in programming a new PLC system?

The ability to systematically program a PLC solution is vital. Show expertise.

-

What safety best practices do you follow when working with live PLCs?

Programming flaws can dangerously disrupt manufacturing. Prove safety mindfulness.

-

How do you optimize PLC code for maximum performance?

Improving logic efficiency demonstrates solid skills. Discuss optimization tactics.

-

What technical PLC programming skills would you like to improve?

Ongoing skill development is key in this field. Be ready to identify areas for growth.

-

How do you stay up to date on the latest PLC technologies?

From joining forums to reading industry publications – highlight efforts made.

-

Why do you want to program PLCs?

Convey genuine passion and fit for the real-world challenges demanded.

Key Takeaways: Skills Needed to Become a Proficient PLC Programmer

- Learn major PLC programming languages – emphasize ladder logic

- Master hardware configuration, wiring, and troubleshooting

- Develop analytical and problem-solving abilities

- Understand digital logic and electrical schematics

- Gain broad PLC platform experience across brands

- Blend programming theory with practical application

- Continue honing skills throughout your career

The world of PLC programming offers great opportunities for those passionate about industrial automation. We hope this overview has made the path to becoming a proficient PLC programmer clearer while highlighting why these skills are so valued by manufacturing companies.

With complex processes only poised to expand further, skilled PLC programmers will continue seeing strong demand. Follow this guide and focus on the right areas to gain this highly valuable skill set.

Work with Automation Ready Panel’s expert PLC programmers today. Check out also our PLC Programming services.

-

Large Process Automation: Panelview 5000, ControlLogix 5580

$24,073.00 Select options -

Small Process Automation: Panelview 5000, ControlLogix 5580

$20,321.00 Select options -

Small Process Automation: ControlLogix 5580, UPS Battery Backup, Cellular Modem

$18,999.00 Select options -

Advanced Automation: Panelview 5000, Safety CompactLogix 5380

$10,269.00 Select options