INDUSTRIAL AUTOMATION EXPERTS

We design Industrial Automation Solutions to increase productivity, elevate quality standards, and lower per-unit manufacturing costs.

Industrial Automation is the process of engaging and evaluating a customers needs and pains, then applying control systems to their factory processes to streamline production with higher throughput, better quality, safer equipment, increased production flexibility, and information analysis. The best Industrial Automation solutions include all of these aspects as a starting point, but go beyond by driving toward deeper application understanding better full-line system integration.

Key components and concepts within industrial automation include:

- Control Systems: These systems manage the operation of machines, processes, and equipment. They can range from simple relay-based control to more sophisticated programmable logic controllers (PLCs) and distributed control systems (DCS) that can handle complex tasks and coordinate multiple devices.

- Sensors and Actuators: Sensors are used to gather data from the environment, such as temperature, pressure, humidity, and more. Actuators, on the other hand, are used to control physical processes, such as motors, valves, and pumps. These components provide real-time feedback to the control system, enabling it to make informed decisions.

- Human-Machine Interface (HMI): The HMI allows operators and engineers to interact with the automation system. This interface can be a graphical user interface (GUI) displayed on a computer screen or physical buttons and switches located in a control room.

- Programmable Logic Controllers (PLCs): PLCs are ruggedized computers specifically designed for industrial control applications. They execute logic programs that control various processes and machines. PLCs can handle tasks like sequencing, logic control, timing, and more.

- Supervisory Control and Data Acquisition (SCADA): SCADA systems monitor, gather, and process real-time data from remote locations. They are used to control and manage various processes, providing a centralized view of the entire industrial system.

- Robotics: Industrial robots are used for tasks such as assembly, welding, material handling, and more. They can be programmed to perform repetitive tasks with precision and accuracy, leading to increased efficiency and reduced labor costs.

- Process Automation: This involves automating complex processes in industries such as chemical, oil and gas, pharmaceuticals, and food production. It often requires specialized control strategies to maintain the desired product quality and safety standards.

- Machine Vision: Machine vision systems use cameras and image processing software to inspect and analyze products on the production line. They can detect defects, measure dimensions, and ensure product quality.

- IoT and Connectivity: The Industrial Internet of Things (IIoT) involves connecting devices, machines, and systems to the internet for data collection and analysis. This connectivity enables better monitoring, predictive maintenance, and optimization of industrial processes.

Industrial automation offers numerous benefits, including increased production speed, improved product quality, reduced downtime, enhanced worker safety, and better utilization of resources. However, implementing and maintaining an automation system requires careful planning, design, integration, and ongoing maintenance to ensure smooth operations and optimal outcomes.

Below is the process Automation Ready Panels uses to design Industrial Automation solutions. We work with you to determine the best controls system to fit your operational needs today and into the future.

Our Industrial Automation Design Process

Discovering Customer Needs

Collaborating For Deep Understanding

You and your team work hard at daily operational improvements. You have a lot of understanding around what your current state and future state look like. This is where we start engaging in the conversation. Using Lean tools like the A3, 5-whys, and others, we can dive deeply into the contributing causes and develop a root cause to current state issues. Once those are determined, a gap analysis can quickly lead to an industrial automation systems solutions approach. This is when a proposal with the best value proposition can be generated.

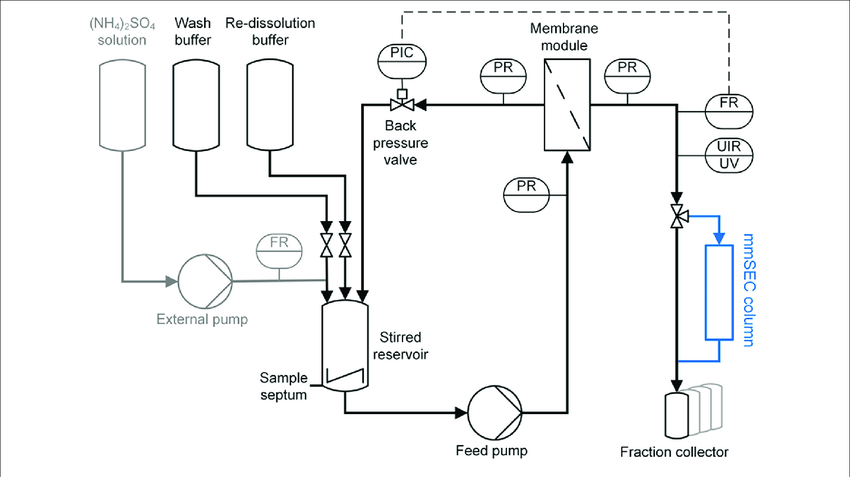

Creating a Process Diagram

Let's Outline A New Solution

A General Arrangement Drawing or P&ID (Process and Instrumentation Diagram) is the best way to gain an architectural view of what the new industrial automation system will be automating. These diagrams show all of the instrumentation, motors, vessels involved, and even show process flow direction. They are great for creating a labeling/tagging schema as a basis for hardware and software design, but also to show how devices and motors interact. Missing instruments that could be valuable to the operation can also be more easily evaluated with this overview.

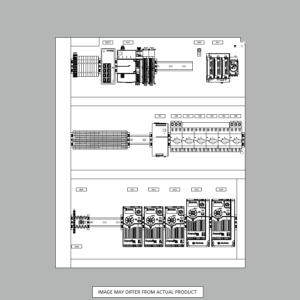

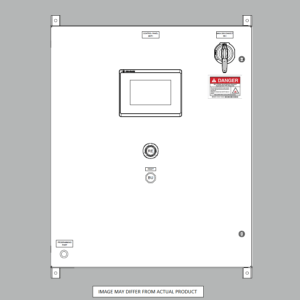

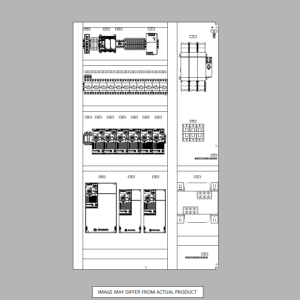

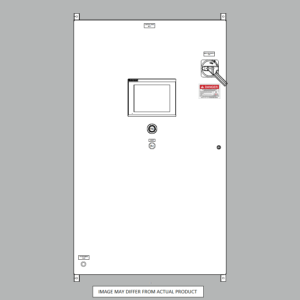

Designing the Hardware

Industrial Automation System Panel Design

We start with specifying UL 508A components needed to accomplish the technical requirements from the P&ID along with the business needs. We make sure these components are of name brand and high quality to ensure your investment lasts for decades into the future. Then we create the AutoCAD Electrical layout drawings, network architecture diagram, and electrical wiring schematics.

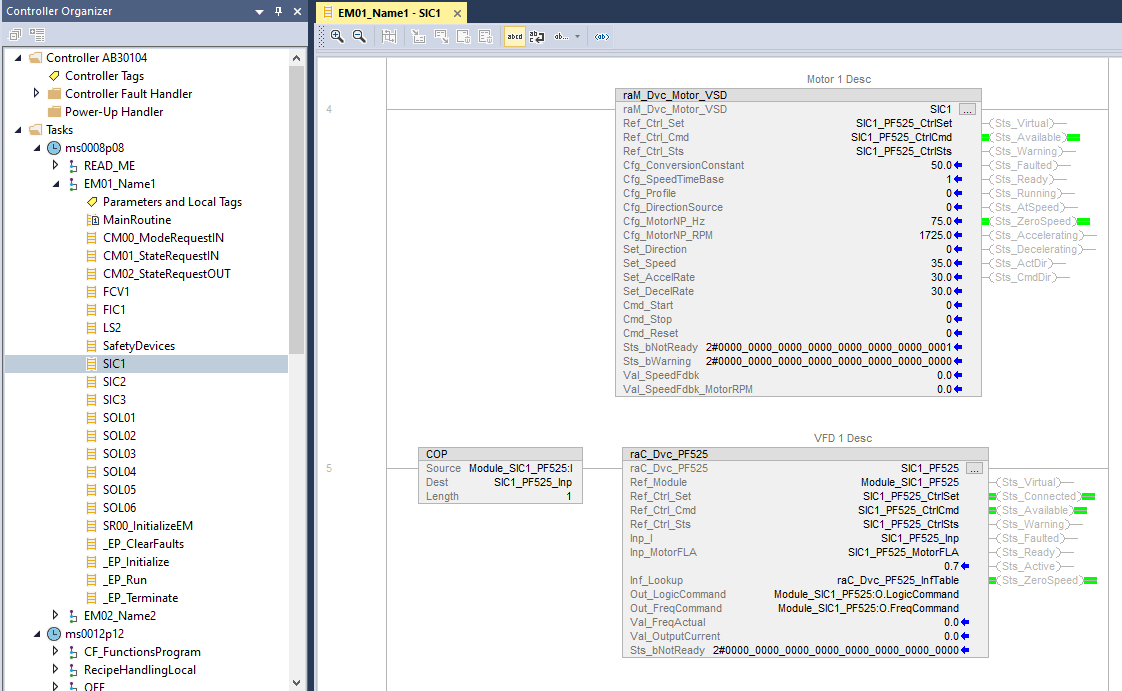

Industrial Automation System Programming

Innovative Logic with Simplistic Layout

We strive to use as much externally-supported "off-the-shelf" logic and graphics as possible. This means that getting questions answered from multiple vendors and sources is possible. Using standards such as Rockwell Automation's PlantPAX, Machine Builder Library, Sample Code Library, ISA-101 HMI design standards, and ISA-88 programming standards, our programming logic is considered the gold standard in the industry.

Simulating Our Work

Ensuring Optimal Industrial Automation Operations

We test our programming before it is shipped to catch any one-offs or edge cases that were not thought of during development. This also gives the customer a good opportunity to see how the control system will operate before it arrives to them. Any functional or aesthetic changes can be reviewed easily using remote conferencing software.

Supporting You

Installation and Troubleshooting Support

Once you are ready to install and start up your new industrial automation system, we are here to help. Our knowledgeable engineers can quickly resolve any questions or changes needed using this Industrial Automation design process. All design aspects are clearly defined, so changes become simplistic. We also enjoy building relationships and keeping in touch with our customers as their needs change over time.