RTD vs Thermocouple

RTD vs Thermocouple

RTD and thermocouple devices are both types of temperature sensors used in industrial and commercial applications. While they may appear similar, they have distinct characteristics and uses that make them suitable for different applications.

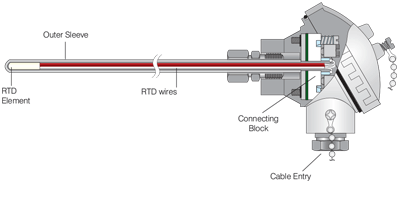

An RTD, or resistance temperature detector, is a type of temperature sensor that measures temperature by measuring the resistance of a material as it changes with temperature. The most common RTDs are made of platinum, which has a very high resistance and a very stable resistance-temperature characteristic over a wide temperature range. RTDs are highly accurate and have a wide temperature range, making them well-suited for applications that require precise temperature control. They are commonly used in the petrochemical, nuclear, and aerospace industries, as well as in laboratory and research settings.

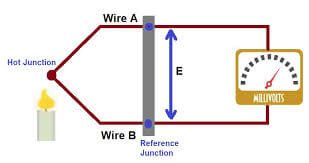

A thermocouple, on the other hand, is a type of temperature sensor that measures temperature by measuring the voltage difference between two dissimilar metal wires. The most common thermocouples are made of iron and constantan, copper and constantan, or nickel and chromium. Thermocouples are inexpensive, rugged, and have a wide temperature range, making them well-suited for applications that require a low-cost, reliable temperature sensor. They are commonly used in the HVAC and appliance industries, as well as in industrial processes that require a quick response time.

One of the main differences between RTDs and thermocouples is their accuracy. RTDs are more accurate than thermocouples, but thermocouples are less expensive and have faster response times. RTDs are also more sensitive to ambient temperature changes, whereas thermocouples are less affected by these changes.

Another difference between the two is the materials they are made of. RTDs are typically made of platinum while thermocouples are made of different metal alloys like iron and constantan, copper and constantan, or nickel and chromium.

In summary, RTDs and thermocouples are both types of temperature sensors, but they have distinct characteristics and uses. RTDs are highly accurate and have a wide temperature range and commonly used in the petrochemical, nuclear, and aerospace industries and laboratory and research settings, while thermocouples are inexpensive, rugged, and have a wide temperature range and commonly used in the HVAC and appliance industries and industrial processes that require a quick response time.

Still confused about RTD and Thermocouple devices? Need to bounce your questions off an expert? Contact Us

SHOP NOW

-

Large Process Automation: Panelview 5000, ControlLogix 5580

$24,073.00 Select options -

Small Process Automation: Panelview 5000, ControlLogix 5580

$20,321.00 Select options -

Small Process Automation: ControlLogix 5580, UPS Battery Backup, Cellular Modem

$18,999.00 Select options -

Advanced Automation: Panelview 5000, Safety CompactLogix 5380

$10,269.00 Select options