Smart Manufacturing: Transforming Industry 4.0 for Efficiency

Smart manufacturing solutions are rapidly changing the landscape of production and manufacturing in today’s Industry 4.0 era. They leverage advanced technologies like artificial intelligence, IoT, and 5G to build interconnected, intelligent, and automated factory environments.

Whether you’re a manufacturer or simply curious about the future of production, this article will give you insight into how smart manufacturing is revolutionizing products and processes on the factory floor.

What Defines Smart Manufacturing?

Smart manufacturing is a holistic strategy that combines technologies like the Industrial Internet of Things (IIoT), cloud computing, big data analytics, and artificial intelligence. Unlike traditional manufacturing, which relies heavily on manual labor and isolated systems, smart manufacturing emphasizes digital transformation and automation convergence. Leveraging real-time data and analytics creates an interconnected environment where manufacturers can make informed decisions to boost productivity and reduce costs.

Why Smart Manufacturing Is Worth Embracing

Traditional manufacturing processes often lack agility and flexibility, leading to inefficient production lines. By adopting smart manufacturing, companies can use smart technologies to adapt quickly to changing market demands. This adaptability makes maintaining high-quality standards easier, reducing downtime and streamlining manufacturing processes. Smart manufacturing also promotes collaboration across supply chains, ensuring all stakeholders are aligned.

How Does Smart Manufacturing Transform the Factory Floor?

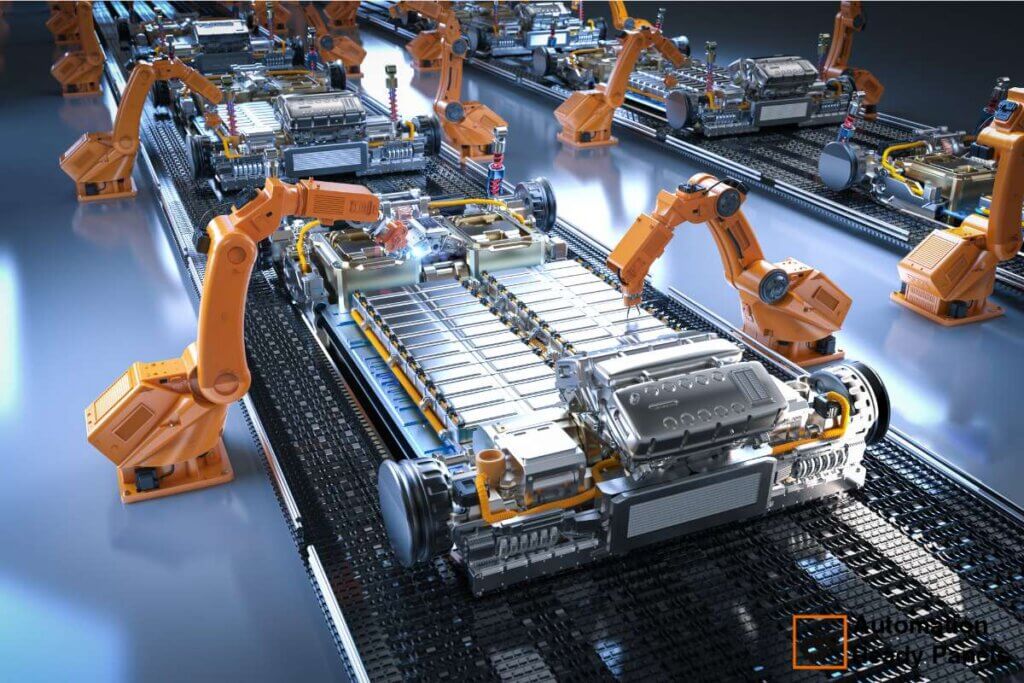

Through smart manufacturing technologies, the factory floor is transformed into an interconnected network of intelligent devices and systems. Devices equipped with sensors collect real-time data, which is analyzed using software solutions like enterprise resource planning (ERP) systems and machine learning algorithms. The insights provided by these analyses help manufacturers automate production lines, optimize workflow, and minimize human error.

Autonomous Manufacturing Processes

Smart manufacturing also enables autonomous production processes, allowing machines to make decisions based on data insights. For instance, robotics systems can automatically adjust production parameters to ensure consistent product quality. Augmented reality (AR) can guide operators through complex tasks, reducing the learning curve for new employees and increasing overall productivity.

What Is Industry 4.0 and Its Connection to Smart Manufacturing?

Industry 4.0, the fourth industrial revolution, represents the evolution of technology in manufacturing. It combines the Industrial Internet of Things, artificial intelligence, robotics, and 5G connectivity to create a smarter, more efficient factory environment. In Industry 4.0, manufacturing data from machines is collected in real-time and analyzed to optimize production and predict equipment failures before they happen.

The Evolution of Technology in Manufacturing

Industry 4.0 has significantly shifted the way manufacturers approach production. Integrating technologies like machine learning, edge computing, and smart manufacturing software solutions has enabled companies to automate manufacturing processes, improve quality control, and make more data-driven decisions.

How Do Smart Manufacturing Solutions Impact Supply Chain Management?

Supply chain resilience is crucial in today’s fast-paced market, where disruptions can have significant consequences. Smart manufacturing gives manufacturers real-time visibility into their supply chains, allowing them to identify potential issues before they cause delays. By using predictive analytics and digital transformation strategies, manufacturers can optimize inventory management, reduce lead times, and ensure quality products reach customers on time.

Improved Collaboration and Communication

Manufacturers can use collaborative tools to improve communication across departments and supply chain partners. By sharing real-time data insights and aligning their strategies, stakeholders can make informed decisions about production schedules, inventory levels, and customer demand.

The Role of AI and Machine Learning in Manufacturing

Artificial intelligence (AI) and machine learning are essential for smart manufacturing, providing manufacturers with powerful tools to analyze vast amounts of data. Predictive analytics algorithms identify patterns and trends, enabling manufacturers to anticipate equipment failures and streamline production processes.

Reducing Human Error and Downtime

Predictive analytics and AI help manufacturers avoid costly downtime and reduce human error by automating routine tasks and providing actionable insights. With these tools, manufacturers can transform their traditional manufacturing workflows into more efficient and productive systems.

Predictive Analytics and Maintenance in Smart Manufacturing

Predictive maintenance is a foundational aspect of smart manufacturing, as it allows manufacturers to anticipate potential equipment failures and schedule maintenance only when needed. This minimizes downtime and ensures a consistent workflow, reducing costs and maximizing productivity.

The Power of Predictive Analytics

Predictive analytics uses real-time data collected from sensors on the factory floor to identify patterns that indicate impending failures. Manufacturers can schedule maintenance proactively, avoiding unexpected breakdowns and extending equipment lifespan.

Why Are Connectivity and 5G Crucial for Smart Manufacturing Technologies?

Connectivity is the backbone of smart manufacturing, enabling devices to communicate and share real-time data across the factory floor. Wireless technologies like Wi-Fi and 5G are crucial for ensuring rapid data exchange, as they provide the bandwidth and low latency needed for seamless communication.

5G and Edge Computing

5G connectivity and edge computing reduce the time to send data between machines, allowing manufacturers to monitor and adjust production processes in real-time. This immediate feedback loop is crucial for minimizing downtime and optimizing efficiency.

How Digital Twins Support Smart Factories

A digital twin is a virtual model of a physical manufacturing process that provides valuable insights into machine performance and workflow optimization. By mirroring the factory floor, digital twins allow manufacturers to simulate production changes and identify potential bottlenecks before implementing them.

Testing and Refining Production Processes

With digital twins, manufacturers can test new insights, refine workflows, and optimize production schedules without risking downtime or disrupting operations. This simulation capability also supports predictive maintenance by identifying equipment that may require servicing.

Benefits of Smart Manufacturing: Efficiency and Quality

The benefits of smart manufacturing are clear: improved efficiency, reduced costs, and high-quality products. By leveraging automation and real-time data, manufacturers can streamline workflows, minimize waste, and produce more consistently high-quality products.

Reduced Costs and Improved Sustainability

Smart manufacturing solutions help reduce costs by minimizing downtime, optimizing inventory management, and streamlining supply chains. They also promote sustainability by reducing energy consumption and waste production.

Cybersecurity Challenges in the Age of Smart Manufacturing

With the increasing reliance on digital technologies and interconnected systems, cybersecurity is a critical consideration for smart manufacturing. Manufacturers must safeguard sensitive intellectual property and production data from cyber threats to maintain supply chain resilience and customer trust.

Securing Manufacturing Data and Intellectual Property

By implementing strong cybersecurity measures, manufacturers can secure their digital transformation journey and protect valuable intellectual property from unauthorized access or theft.

Change Management in Smart Manufacturing

Transitioning to smart manufacturing requires careful change management. This process involves aligning initiatives across departments, training employees on new systems, and ensuring all stakeholders understand the benefits of adopting smart technologies.

Collaborative Change Management Strategies

Manufacturers should adopt collaborative change management strategies that encourage cross-departmental communication and align goals. By involving employees in the transition process, companies can reduce resistance to change and accelerate the adoption of smart manufacturing solutions.

Key Takeaways

- Smart Manufacturing Principles: A holistic strategy integrating digital transformation to boost productivity and streamline manufacturing processes.

- Industry 4.0 Impact: Industry 4.0 combines advanced technologies like IoT, AI, and 5G to create smart factories.

- Supply Chain Resilience: Smart manufacturing strengthens supply chain management by leveraging real-time data.

- AI and Predictive Analytics: Artificial intelligence and predictive analytics automate tasks and minimize downtime.

- Connectivity and 5G: Wireless connectivity and 5G enable seamless real-time data exchange.

- Digital Twins: Virtual models simulate production changes and support predictive maintenance.

- Cybersecurity: Strong cybersecurity measures protect manufacturing data and intellectual property.

- Change Management: Collaborative change management strategies align stakeholders and accelerate the transition.

Smart manufacturing has transformed the way we approach production and manufacturing. By adopting these technologies, manufacturers can navigate the challenges of Industry 4.0, improve supply chain resilience, and stay competitive in today’s rapidly evolving market. If you’re needing help on how make your current manufacturing processes smarter, talk to us at Automation Ready Panels today.

-

Large Process Automation: Panelview 5000, ControlLogix 5580

$24,073.00 Select options -

Small Process Automation: Panelview 5000, ControlLogix 5580

$20,321.00 Select options -

Small Process Automation: ControlLogix 5580, UPS Battery Backup, Cellular Modem

$18,999.00 Select options -

Advanced Automation: Panelview 5000, Safety CompactLogix 5380

$10,269.00 Select options