Automation in Fracking with the Help of PLC

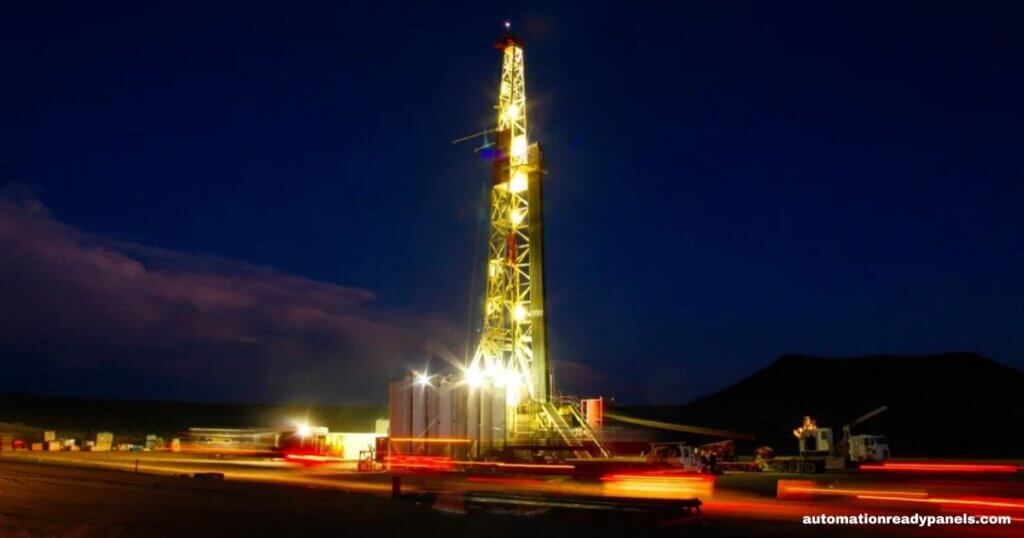

Fracking, or hydraulic fracturing, is a modern oil and gas extraction cornerstone. Yet, this complex process often presents challenges, such as optimizing efficiency, maintaining safety, and minimizing operational downtime. What role does automation play in solving these issues? How do programmable logic controllers (PLCs) fit into this equation? And most importantly, how can companies integrate automation efficiently without disrupting existing workflows?

This article explores how PLC automation transforms fracking operations, delivering greater control, scalability, and operational safety. We’ll also showcase how Automation Ready Panels offers fast, reliable, high-quality PLC solutions tailored to the oil and gas industry.

What is Fracking Automation, and Why is it Important?

Hydraulic fracturing requires precision and control to maximize resource recovery while minimizing risks. Automation addresses these challenges by enabling real-time monitoring, adaptive adjustments, and fail-safe systems that ensure operations run smoothly.

By incorporating PLCs, fracking operators can efficiently:

- Control critical processes such as fluid injection and pressure monitoring.

- Detect and prevent system faults before they cause significant downtime.

- Enhance safety protocols through automated shutdowns and alarm systems.

Automation is no longer a luxury but a necessity for staying competitive in the fast-paced oil and gas industry.

How PLCs Revolutionize Fracking Operations

Key Benefits of PLC Automation in Fracking

- Unmatched Precision and Control

PLCs are designed to handle complex operations with absolute precision. For example, maintaining the ideal flow rate of water, sand, and chemicals during fracking ensures consistent well productivity without overburdening the system. - Real-Time Monitoring and Adjustments

PLCs gather real-time data on pressure levels, equipment conditions, and flow rates. Operators can make data-driven decisions instantly, allowing adjustments before minor issues escalate into costly shutdowns. - Reduced Human Error

Human operators are prone to fatigue, distractions, and inconsistencies. By automating repetitive and critical tasks, PLCs significantly reduce the likelihood of errors that could impact safety or production quality. - Scalability for Growing Operations

As oil and gas companies expand their fracking sites, PLCs provide modular and scalable solutions that can grow alongside operational demands without extensive reprogramming. - Sustainability and Cost Savings

Efficient PLC systems minimize energy waste by optimizing processes, such as maintaining equipment at peak performance. This not only saves on operational costs but also reduces environmental impacts.

Automation Ready Panels: Your Trusted Partner for PLC Solutions

Automation Ready Panels offers a game-changing approach to automation in the oil and gas sector. With our pre-designed PLC control panels, companies can achieve seamless integration and enjoy robust functionality without the long lead times often associated with custom-built solutions.

Why Automation Ready Panels?

- Speed and Efficiency: We understand the time-critical nature of fracking projects. That’s why our panels are designed, built, and delivered fast. Built without compromising quality.

- Customization Options: While our panels come pre-designed, they can be tailored to your specific operational needs.

- Proven Reliability: We can design your panels to withstand the harsh conditions of fracking sites, from extreme temperatures to high vibrations. Just let us know.

- Made in the USA: By partnering with us, you’ll support American manufacturing and ensure consistent quality standards.

Our Services and Solutions

Automation Ready Panels specializes in:

- Pre-Designed PLC Panels: Ready-to-use control panels that are pre-programmed for seamless deployment.

- Fast Delivery: Streamlined processes ensure your equipment is shipped on time, every time.

- Support and Expertise: Our team offers consultation services to ensure your panels are integrated smoothly and operate efficiently.

Maximize Performance with PLC+ Care Service

Investing in automation is just the first step—ongoing monitoring and support are essential to maintaining peak performance. That’s where PLC+ Care comes in.

What Is PLC+ Care?

PLC+ Care is a specialized service designed to ensure your industrial PLC systems operate at maximum efficiency through:

- Industrial PLC Data Collection – Gain actionable insights from real-time operational data.

- Live Data Monitoring – Track system performance 24/7 for proactive issue detection.

- Post-Startup Support – Receive expert assistance to optimize system functionality.

Why Choose PLC+ Care?

- Proactive System Monitoring: Identify and resolve potential issues before they cause downtime.

- Fast Troubleshooting: Minimize disruptions with immediate support and remote diagnostics.

- Optimized Automation Solutions: Continuously improve efficiency and maximize ROI on your automation investment.

With PLC+ Care, you’re not just automating—you’re ensuring long-term reliability, performance, and support.

FAQs About PLC Automation in Fracking

Q: How can PLC automation improve the safety of fracking operations?

A: PLC systems are equipped with fail-safes and automated shutdown protocols that activate instantly when abnormal conditions, such as pressure surges, are detected. This protects both workers and equipment.

Q: Is automation suitable for small-scale fracking sites?

A: Absolutely. PLCs are scalable, making them ideal for both small operations and large, multi-site fracking projects. Our pre-designed panels are versatile and adaptable to any scale.

Q: Can Automation Ready Panels’ solutions integrate with my existing systems?

A: Yes. Our pre-designed PLC control panels are compatible with most fracking setups, ensuring a seamless integration process.

Q: How quickly can you deliver a PLC panel?

A: Thanks to our streamlined production process, Automation Ready Panels delivers high-quality panels in a fraction of the time required for custom solutions.

Q: Are your panels built to handle harsh environmental conditions?

A: Yes, they can be designed this way upon request. Our panels can be designed to withstand the tough conditions typically found in fracking operations, including temperature extremes, moisture, and vibration.

Conclusion: Partner with Automation Ready Panels

The integration of PLC-based automation transforms fracking operations, helping companies enhance efficiency, improve safety, and reduce operational costs. Embracing automation is essential for oil and gas businesses looking to remain competitive in a demanding industry.

Automation Ready Panels provides the tools and expertise you need to unlock these benefits. Our pre-designed and pre-programmed PLC panels offer an efficient, high-quality, and reliable solution for automating your operations.

Contact us today at (636) 357-8155 or visit Automation Ready Panels to learn more about how we can support your fracking automation needs.

-

Large Process Automation: Panelview 5000, ControlLogix 5580

$24,073.00 Select options -

Small Process Automation: Panelview 5000, ControlLogix 5580

$20,321.00 Select options -

Small Process Automation: ControlLogix 5580, UPS Battery Backup, Cellular Modem

$18,999.00 Select options -

Advanced Automation: Panelview 5000, Safety CompactLogix 5380

$10,269.00 Select options