Everything You Need to Know About Basic Automation Panels

Basic automation panels are a cornerstone of efficient and effective industrial operations. These panels streamline processes, improve productivity, and reduce downtime, making them essential for businesses in manufacturing, logistics, and other industries.

If you’re looking for a reliable provider in the U.S., Automation Ready Panels offers customized solutions to meet your automation needs. This article dives deep into the essentials of basic automation panels, their benefits, and why partnering with the right provider is critical for success.

What Are Basic Automation Panels?

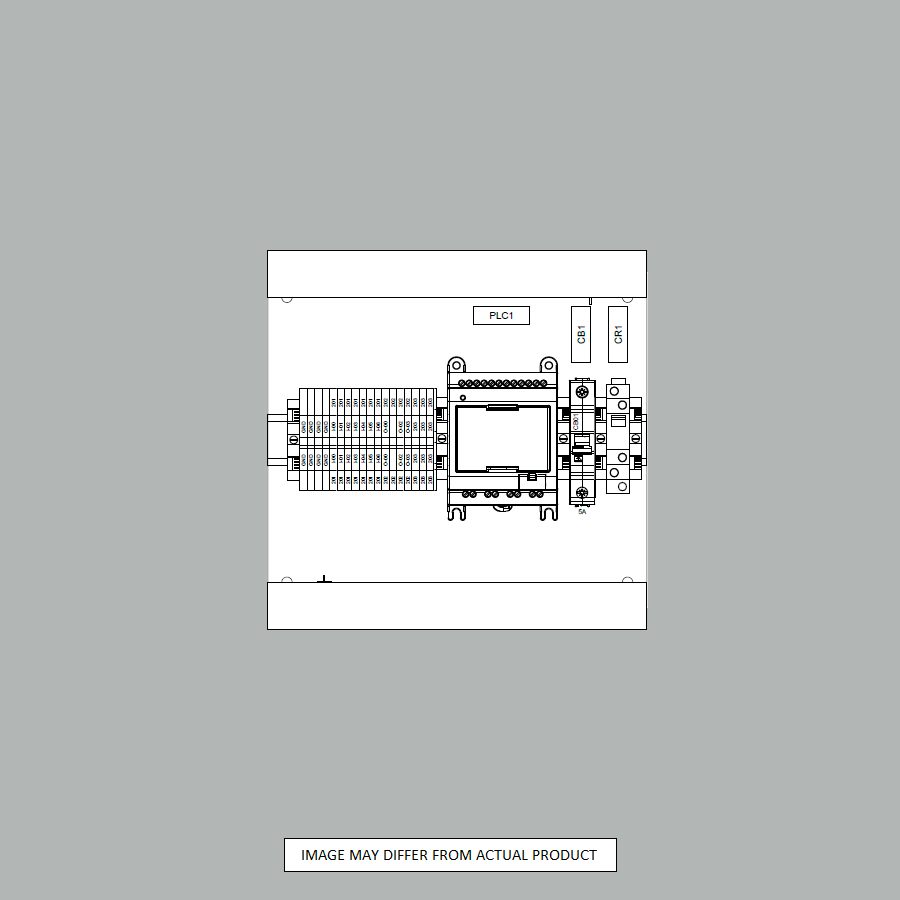

Basic automation panels are electrical control systems designed to manage and automate specific processes or equipment in a facility. These panels:

- Serve as the interface between machinery and operators.

- Include essential components such as programmable logic controllers (PLCs), human-machine interfaces (HMIs), relays, and switches.

- Are customizable to fit various industrial applications, from controlling conveyor belts to automating entire production lines.

Features of Basic Automation Panels:

Basic automation panels are built with several features that make them indispensable for industrial applications. These features ensure seamless operation, flexibility, and safety.

1. Custom Design

Automation panels are tailored to meet the unique needs of your processes. Whether you’re running a manufacturing line, monitoring energy distribution, or managing warehouse operations, custom designs allow for:

- Specific voltage and amperage requirements.

- Compatibility with existing systems.

- Expansion capabilities to support future growth.

2. User-Friendly Interfaces

Modern panels often include human-machine interfaces (HMIs), which make it easy for operators to monitor and control equipment. Key benefits include:

- Real-time data visualization on touchscreens.

- Intuitive controls, reducing the learning curve for operators.

- Multi-language support for diverse workforces.

3. Safety Measures

Automation panels prioritize safety, incorporating features such as:

- Circuit Breakers: Prevent overloads and protect equipment.

- Emergency Stop Buttons: Quickly shut down operations during malfunctions.

- Alarms and Indicators: Alert operators to potential issues before they escalate.

4. Energy Efficiency

Modern panels are designed to optimize energy use, featuring:

- Smart relays that adjust power consumption.

- Sensors that shut down idle machinery.

- Energy monitoring systems for cost tracking and reduction.

Benefits:

Investing in automation panels offers numerous advantages, from boosting efficiency to enhancing workplace safety.

1. Increased Operational Efficiency

Automation panels streamline repetitive tasks and complex processes, allowing businesses to:

- Operate machinery 24/7 without fatigue.

- Eliminate bottlenecks in production lines.

- Monitor system performance in real-time for quick adjustments.

2. Cost Savings

Automation reduces operational costs by:

- Cutting labor expenses through reduced manual intervention.

- Minimizing errors that can lead to waste or rework.

- Lowering energy usage with smart power management.

3. Improved Product Quality

Consistent automation results in uniform output quality, as processes are carried out with precision. Automated panels ensure:

- Exact adherence to manufacturing specifications.

- Consistency across production batches.

- Lower defect rates compared to manual operations.

4. Enhanced Workplace Safety

By automating high-risk or repetitive tasks, panels reduce the likelihood of workplace accidents. Built-in safety features also minimize equipment-related hazards.

5. Scalability and Flexibility

Automation panels can grow with your business. You can:

- Add new components or machinery without replacing the entire system.

- Adapt to changes in product designs or operational requirements.

Why Your Business Needs Automation

Addressing Common Business Challenges

Businesses often face issues such as:

- Rising Labor Costs: Manual operations require more workforce, leading to higher expenses.

- Downtime: Mechanical failures or human errors can result in costly delays.

- Demand for Precision: Customers expect flawless products delivered on time.

Automation panels address these challenges by:

- Streamlining Workflows: Automation ensures processes are carried out faster and more accurately.

- Reducing Reliance on Labor: Fewer manual interventions lead to cost savings.

- Improving Uptime: Real-time monitoring detects potential issues early, preventing prolonged downtime.

Competitive Advantage

In a competitive market, businesses with automation enjoy:

- Faster production cycles.

- Lower operational costs.

- Better adaptability to industry changes.

Industries That Benefit from a Basic Automation Panel

1. Manufacturing

Automation panels play a pivotal role in optimizing production. They manage tasks like:

- Controlling robotic arms for assembly lines.

- Monitoring temperature and pressure in sensitive manufacturing processes.

- Ensuring quality control through integrated sensors.

2. Logistics and Warehousing

Automation panels enhance efficiency in supply chain management by:

- Streamlining conveyor belt operations.

- Automating sorting and packaging systems.

- Managing climate controls in storage facilities.

3. Energy and Utilities

Automation panels are essential in power generation and distribution systems. They:

- Monitor and control energy flow.

- Integrate renewable energy sources, such as solar or wind.

- Optimize power usage in grids to prevent outages.

4. Healthcare and Pharmaceuticals

The healthcare sector relies on automation panels for:

- Managing cleanroom environments in pharmaceutical production.

- Monitoring sterilization processes.

- Automating diagnostic equipment for faster results.

Choosing the Right Provider

When investing in automation panels, selecting the right provider is crucial. Automation Ready Panels, a U.S.-based company, specializes in designing and delivering high-quality automation solutions.

Why Choose Automation Ready Panels?

- Expertise: Decades of experience in creating custom automation solutions.

- Quality Assurance: Panels built with industry-standard components for reliability.

- Customer Support: End-to-end assistance.

Key Components of Automation Panels

Automation panels are composed of various components, each playing a crucial role in system functionality.

1. Programmable Logic Controller (PLC)

The PLC acts as the brain of the panel, controlling the sequence of operations. Benefits include:

- Flexibility: Easily reprogrammed to adapt to process changes.

- Reliability: Designed to perform in harsh industrial environments.

2. Human-Machine Interface (HMI)

The HMI enables operators to interact with the system through:

- Visual dashboards that display real-time data.

- Controls to start, stop, or adjust processes.

- Alerts for system malfunctions or maintenance needs.

3. Relays and Contactors

These components control the flow of electricity:

- Relays ensure safe signal transmission between devices.

- Contactors manage power to larger loads like motors.

4. Sensors and Actuators

- Sensors detect variables such as temperature, pressure, or motion.

- Actuators perform mechanical actions, like opening a valve or moving a robotic arm.

5. Power Supply Units

Power supplies ensure consistent voltage and current, protecting components from damage caused by fluctuations.

6. Communication Modules

These allow the panel to connect with external systems or networks, supporting protocols like Ethernet or Modbus for seamless integration.

How to Maintain Basic Automation Panel

Regular maintenance ensures your panels operate at peak efficiency. Follow these best practices:

- Inspect Regularly: Check for signs of wear or damage.

- Update Software: Keep PLCs and HMIs up-to-date.

- Clean Components: Prevent dust and debris buildup.

- Test Safety Features: Ensure emergency stops and alarms are functional.

Maintenance Checklist

- ☐ Inspect wiring and connections.

- ☐ Verify component functionality.

- ☐ Update system documentation.

- ☐ Schedule annual professional servicing.

Frequently Asked Questions (FAQs)

1. What is the lifespan of a basic automation panel?

With proper maintenance, automation panels can last 10–15 years or more.

2. Can basic automation panel be integrated with existing systems?

Yes, panels can be designed to integrate seamlessly with your current machinery and processes.

3. How do I know if my business needs automation?

If you experience frequent downtime, high labor costs, or inefficiencies, automation could be a game-changer.

4. Are there financing options available for automation solutions?

Many providers, including Automation Ready Panels, offer flexible payment plans to suit your budget.

Final Thoughts

Basic automation panels are a vital investment for businesses looking to optimize operations, reduce costs, and remain competitive in their industries. Partnering with a trusted provider like Automation Ready Panels ensures you receive a tailored, high-quality solution backed by expert support.

Ready to take the next step? Contact Automation Ready Panels today to learn more about our custom automation solutions. Enhance your business efficiency with panels designed for success!

-

Large Process Automation: Panelview 5000, ControlLogix 5580

$24,073.00 Select options -

Small Process Automation: Panelview 5000, ControlLogix 5580

$20,321.00 Select options -

Small Process Automation: ControlLogix 5580, UPS Battery Backup, Cellular Modem

$18,999.00 Select options -

Advanced Automation: Panelview 5000, Safety CompactLogix 5380

$10,269.00 Select options