Assembly Line Robots: Unleashing Efficiency in Production Lines

In modern manufacturing, assembly line robots have emerged as a game-changer, revolutionizing how products are assembled. These means also that these highly advanced machines are designed to perform repetitive tasks with unparalleled precision, speed, and efficiency. This streamlines the production process and ensuring consistent quality. This is also called Robotic Process Automation.

Unleash Efficiency with Robotic Assembly Line Robots

As the demand for consumer goods continues to rise, manufacturers face immense pressure to increase productivity while maintaining high-quality standards. Assembly line robots have become indispensable in achieving these goals, enabling companies to meet the ever-growing demand for products while reducing labor costs and minimizing human errors.

History of Assembly Line Robots

Evolution of Automation in Manufacturing

The concept of automation in manufacturing can be traced back to the Industrial Revolution when mechanization played a pivotal role in transforming the way goods were produced. Over time, technological advancements paved the way for the introducing of assembly line robots, further enhancing the efficiency and accuracy of manufacturing processes.

Introduction of Industrial Robots in Assembly Lines

In the 1960s, the first industrial robots were introduced in assembly lines, primarily for welding and material handling tasks. As technology progressed, these also makes robots became more sophisticated, capable of performing a wider range of tasks with greater precision and speed.

Types of Assembly Line Robots

Articulated Robots

Articulated robots are among the most versatile and widely used in assembly lines. They also feature rotary joints that provide a high degree of flexibility, allowing them to reach and operate in confined spaces easily. They are also commonly employed for welding, painting, and material handling tasks. Fanuc Robots, a leading brand in the industrial robotics market, offers a wide range of articulated robots suitable for various assembly line applications.

SCARA Robots

SCARA (Selective Compliance Articulated Robot Arm) robots are designed for high-speed, repetitive tasks that require precise and rapid movements. These robots are commonly found in electronics assembly lines, where they excel at pick-and-place operations and other intricate tasks involving small parts.

Cartesian Robots

Cartesian or linear robots move along three perpendicular axes (X, Y, and Z). They are often used in assembly lines for packaging, palletizing, and machine tending, where their linear motion and high positional accuracy are advantageous.

Collaborative Robots

Collaborative robots, or cobots, are designed to work alongside human workers in a shared workspace. These robots also have advanced safety features that allow them to operate near humans without risk. Cobots are increasingly used in assembly lines for tasks that require human skill and robotic precision, such as handling small parts or performing precision assembly tasks.

Delta Robots

Delta robots, named for their triangular configuration, are known for their high speed and accuracy. These robots are often employed in assembly lines for high-speed pick-and-place operations, packaging, and other tasks that require rapid and precise movements within a defined work envelope.

Benefits of Using Assembly Line Robots

Benefits of Using Assembly Line Robots

Increased Productivity

Assembly-line robots can work tirelessly around the clock. This also means that it significantly increase the production output compared to manual labor. Their precise and consistent movements ensure that tasks are completed efficiently, minimizing downtime and maximizing productivity. By using robotic assembly processes, manufacturers can more effectively meet their production goals and keep their production lines running at optimal levels.

Improved Quality of Products

Robotic assembly lines greatly reduce the likelihood of human errors. This also results in higher-quality products. Robots perform tasks with unwavering accuracy and repeatability, ensuring that each product meets the specified standards and specifications. This precision and accuracy offered by robots ensure consistent quality in manufacturing, resulting in improved customer satisfaction and reduced waste.

Cost Savings

While the initial investment in robotics can be substantial, the long-term cost savings derived from increased productivity, reduced labor costs, and minimized waste can offset the upfront expenses, making it a financially viable solution for manufacturers. By reducing production time and waste, robotic assembly systems can significantly save costs over time.

Enhanced Worker Safety

Robots can perform hazardous or physically demanding tasks for human workers, such as handling heavy loads, working in environments with extreme temperatures, or handling dangerous materials. By automating these tasks, manufacturers can enhance worker safety and reduce the risk of workplace injuries, allowing human workers to focus on more strategic roles.

Challenges of Implementing Assembly Line Robots

Initial Costs

Acquiring and installing robotic assembly lines can be a significant investment for manufacturers, particularly small and medium-sized enterprises. The costs of purchasing the robots, programming software, and integrating them into the existing infrastructure can be substantial. However, the long-term benefits often outweigh the initial investment.

Training Requirements for Workers

While robots can automate many tasks, human workers are still also required to program, maintain, and oversee robotic assembly lines. Training programs may be necessary to equip workers with the skills needed to operate and maintain these advanced systems effectively, ensuring optimal performance and regular maintenance.

Integration with Existing Infrastructure

Integrating robotic assembly lines into an existing manufacturing facility can be complex. Ensuring compatibility with existing equipment, adapting workflows, and addressing potential bottlenecks or inefficiencies may require significant planning and resources. Choosing the right robot and automation solutions for your needs is crucial for successful integration.

Case Studies of Successful Implementation of Assembly Line Robots

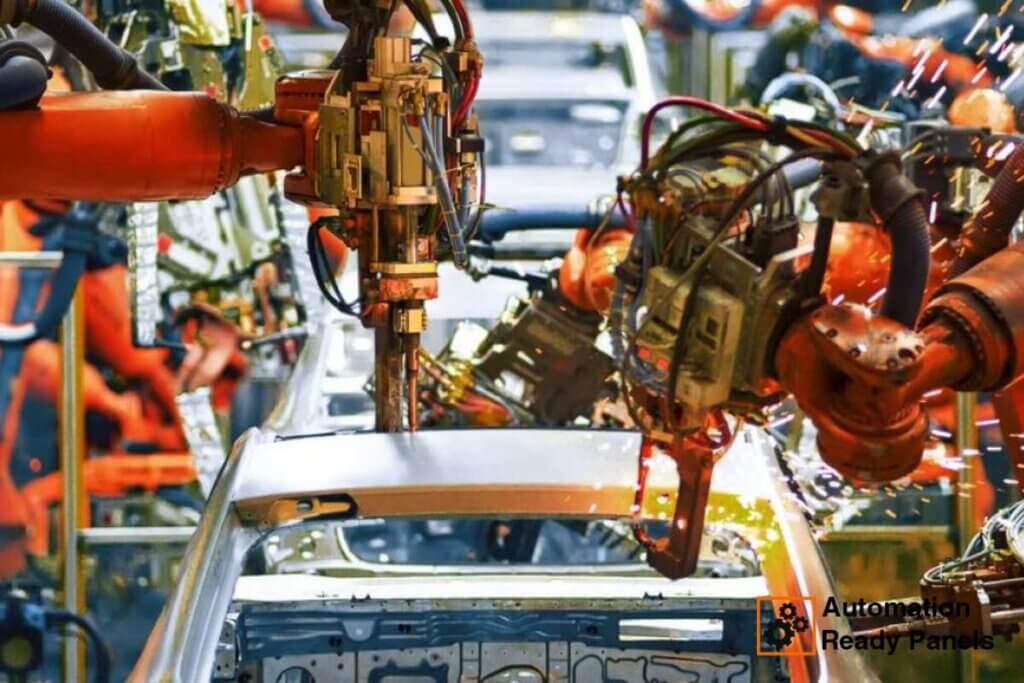

Automotive Manufacturing

Automotive Manufacturing Assembly Line Robots

The automotive industry has been at the forefront of adopting robotic assembly lines. Companies like Toyota, Ford, and General Motors have implemented highly automated assembly processes, utilizing robots for welding, painting, material handling, and precision assembly of car parts. These robotic assembly systems have enabled automakers to increase production efficiency, reduce waste, and deliver high-quality vehicles.

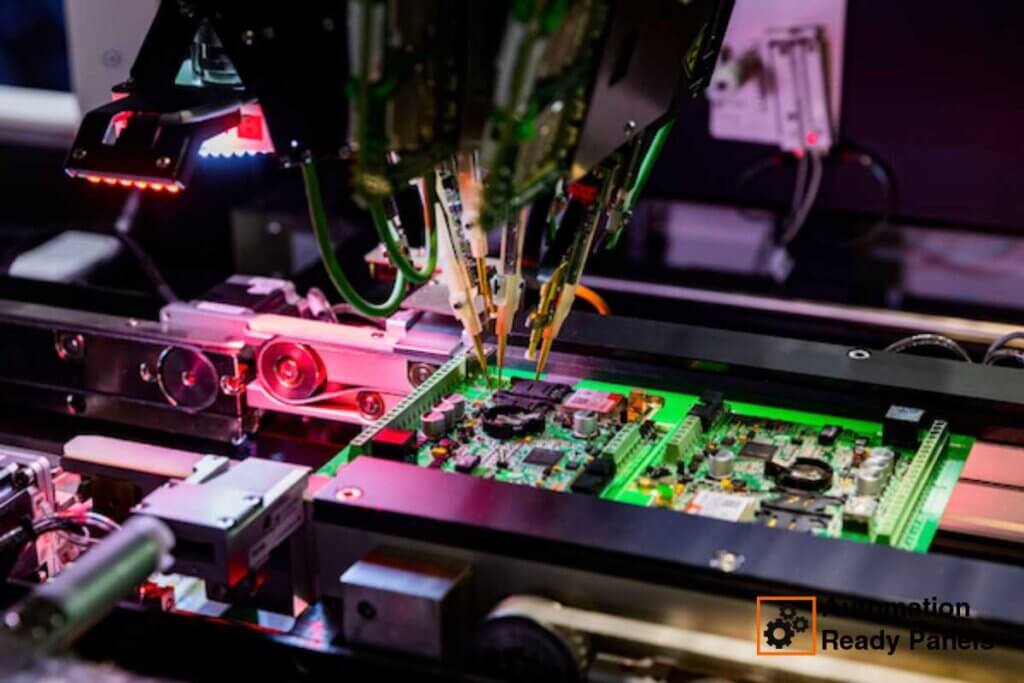

Electronics Manufacturing

Electronics Manufacturing Assembly Line Robots

The electronics industry, known for its fast-paced production cycles and stringent quality requirements, has embraced robotic assembly lines. Apple and Samsung have implemented advanced robotic systems for circuit board assembly, component placement, and product testing. High-speed and precision assembly robots ensure accurate and efficient assembly of intricate electronic devices.

Food and Beverage Production

Assembly line robots have also found applications in the food and beverage industry, where they are used for packaging, palletizing, and quality inspection. Companies like Nestlé and PepsiCo have implemented robotic systems to streamline their production processes and ensure consistent product quality, reducing the risk of errors and contamination.

Future Trends in Assembly Line Robots

Future Trends in Assembly Line Robots

Advances in Artificial Intelligence

Integrating artificial intelligence (AI) into robotic assembly lines is poised to revolutionize manufacturing. AI-powered robots can learn and adapt to changing conditions, optimizing processes and decision-making in real time, leading to further improvements in efficiency and productivity. Machine learning algorithms and sensors allow robots to improve their performance continuously.

Integration with the Internet of Things (IoT)

The Internet of Things (IoT) is transforming manufacturing facilities’ operations. Manufacturers can gather and analyze data in real-time by connecting assembly line robots to a network of smart sensors and devices. This enables predictive maintenance, optimized resource allocation, and improved overall equipment effectiveness (OEE). IoT connectivity also allows remote monitoring and control of robotic assembly systems.

Growth of Collaborative Robots in Manufacturing

As collaborative robots (cobots) continue to evolve, their adoption in manufacturing is expected to grow significantly. These advanced robots can work safely alongside human workers, seamlessly integrating human dexterity and robotic precision. This will ultimately enhance productivity and enable new applications in assembly lines. Cobots can handle tasks that require a combination of flexibility and precision, expanding the range of applications for robotic automation.

Expansion of Robotic Applications

As technology advances, robotic assembly line applications are expected to expand into various industries beyond the traditional automotive and electronics sectors. Industries such as aerospace, medical device manufacturing, and construction are exploring robotic assembly systems to improve quality, reduce errors, and increase efficiency.

Conclusion

Assembly line robots have revolutionized modern manufacturing, offering numerous benefits such as increased productivity, improved product quality, cost savings, and enhanced worker safety. By automating repetitive and often hazardous tasks, these robots have paved the way for more efficient and safer production processes. Whether it’s welding robots, high-speed assembly robots, or collaborative robots, different types of assembly robots can be utilized to meet specific production goals and requirements.

As robotics technology evolves rapidly, manufacturers must also stay informed about the latest advancements and trends. Embracing cutting-edge robotic solutions can provide a competitive edge. This enables companies to streamline their operations, reduce costs, and also meet the ever-changing demands of the global market.

Key Takeaways

- Assembly line robots have become indispensable tools in modern manufacturing, enabling increased productivity, improved quality, and also cost savings.

- Different types of robots, such as articulated, SCARA, Cartesian, and collaborative robots, cater to various assembly line tasks and requirements.

- Successful implementation of assembly line robots requires addressing challenges like initial costs, training requirements, and integration with existing infrastructure.

- Industries like automotive, electronics, and food and beverage have significantly benefited from implementing robotic assembly lines.

- Future trends, including advancements in AI, IoT integration, and the growth of collaborative robots, will further enhance the capabilities and applications of assembly line robots.

By embracing robotic assembly lines and staying up-to-date with the latest technological advancements, manufacturers can position themselves at the forefront of innovation. This ensures sustained competitiveness in an ever-evolving global market. Take a consult call from Automation Ready Panels to start getting expert advices on how you can further increase the efficiency of your manufacturing processes.

-

Large Process Automation: Panelview 5000, ControlLogix 5580

$24,073.00 Select options -

Small Process Automation: Panelview 5000, ControlLogix 5580

$20,321.00 Select options -

Small Process Automation: ControlLogix 5580, UPS Battery Backup, Cellular Modem

$18,999.00 Select options -

Advanced Automation: Panelview 5000, Safety CompactLogix 5380

$10,269.00 Select options