Standard Automation: Single Phase Motors, Panelview 800, Micro820

$2,802.00

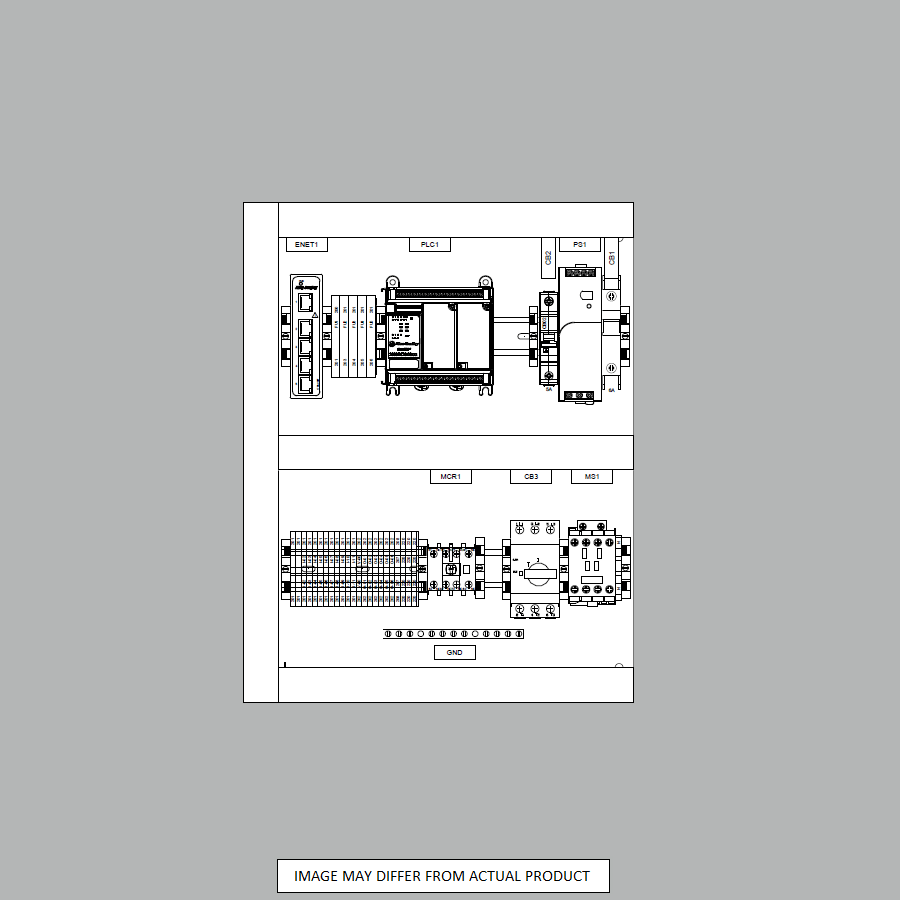

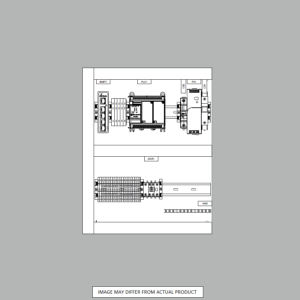

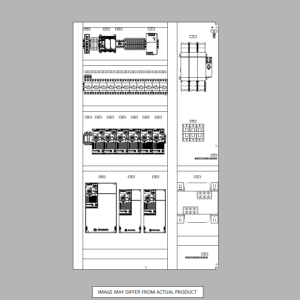

- Up to 30 Amp Feeder Circuit Breaker (depending on number of motors and sizes)

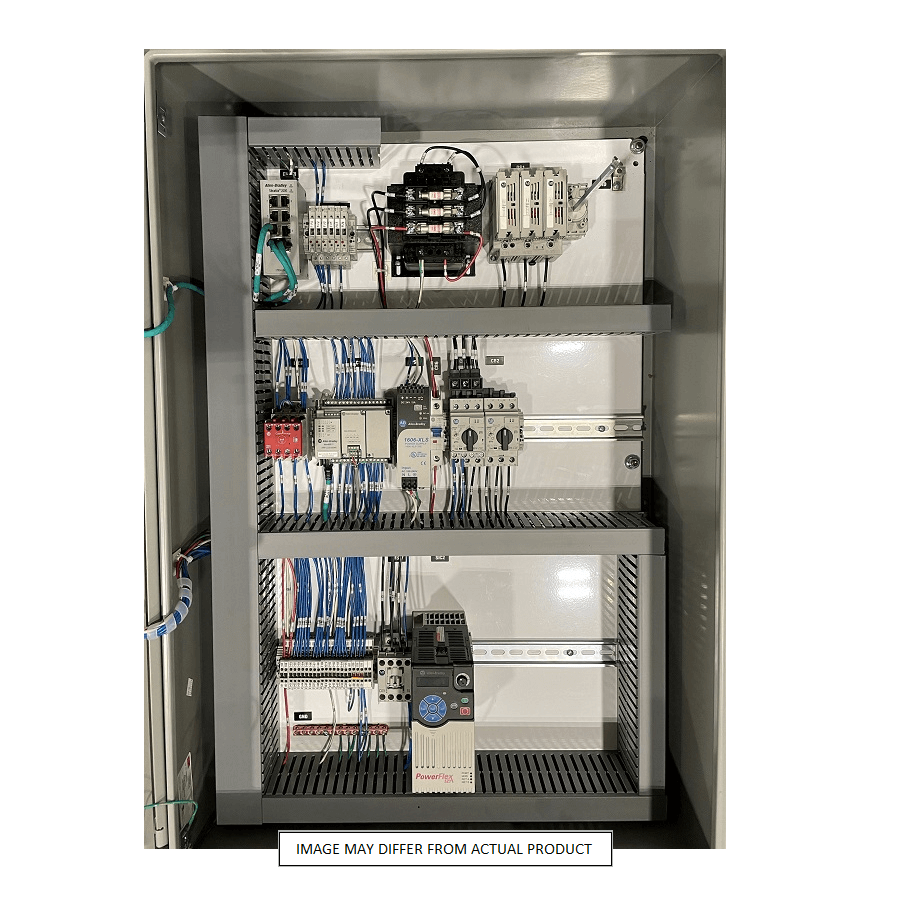

- Allen-Bradley and Hoffman Components used whenever possible

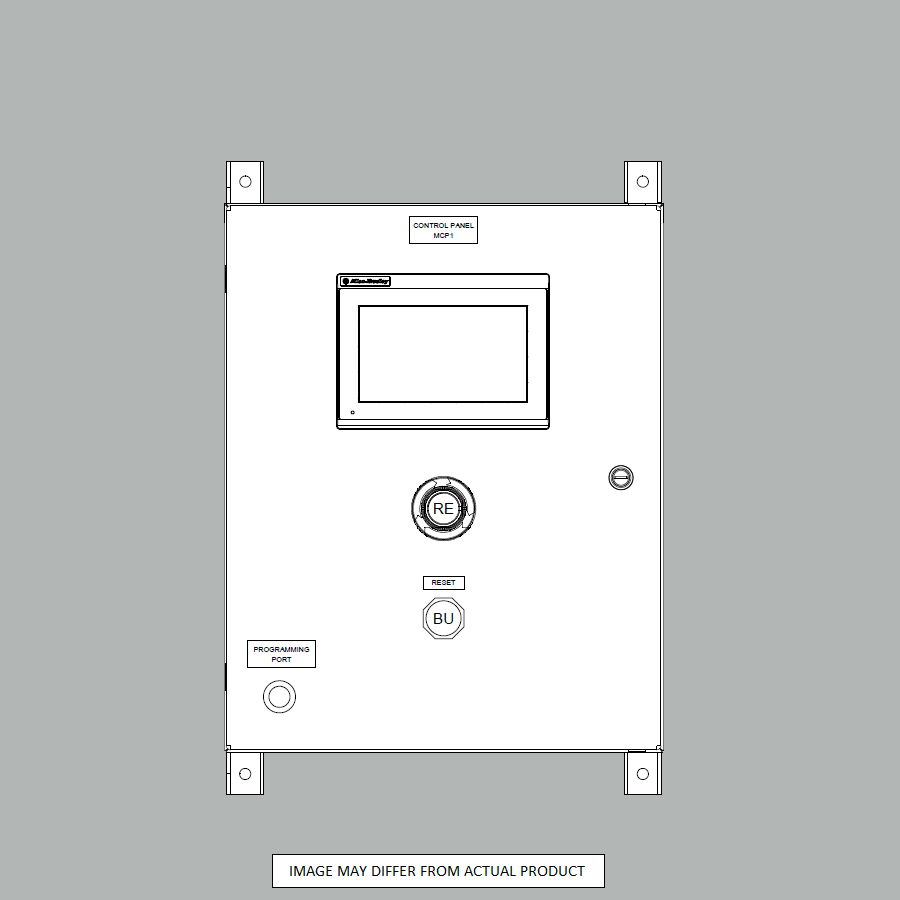

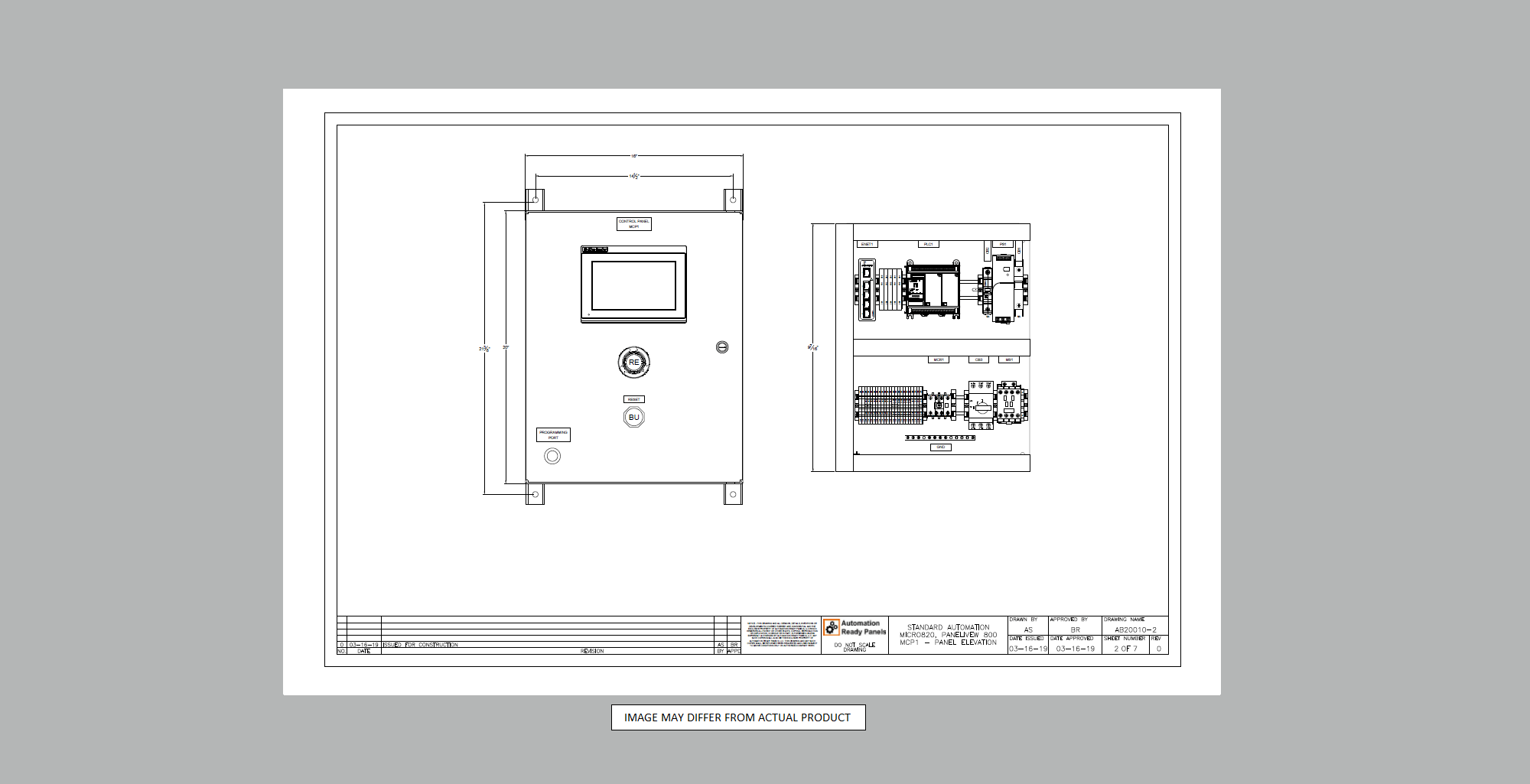

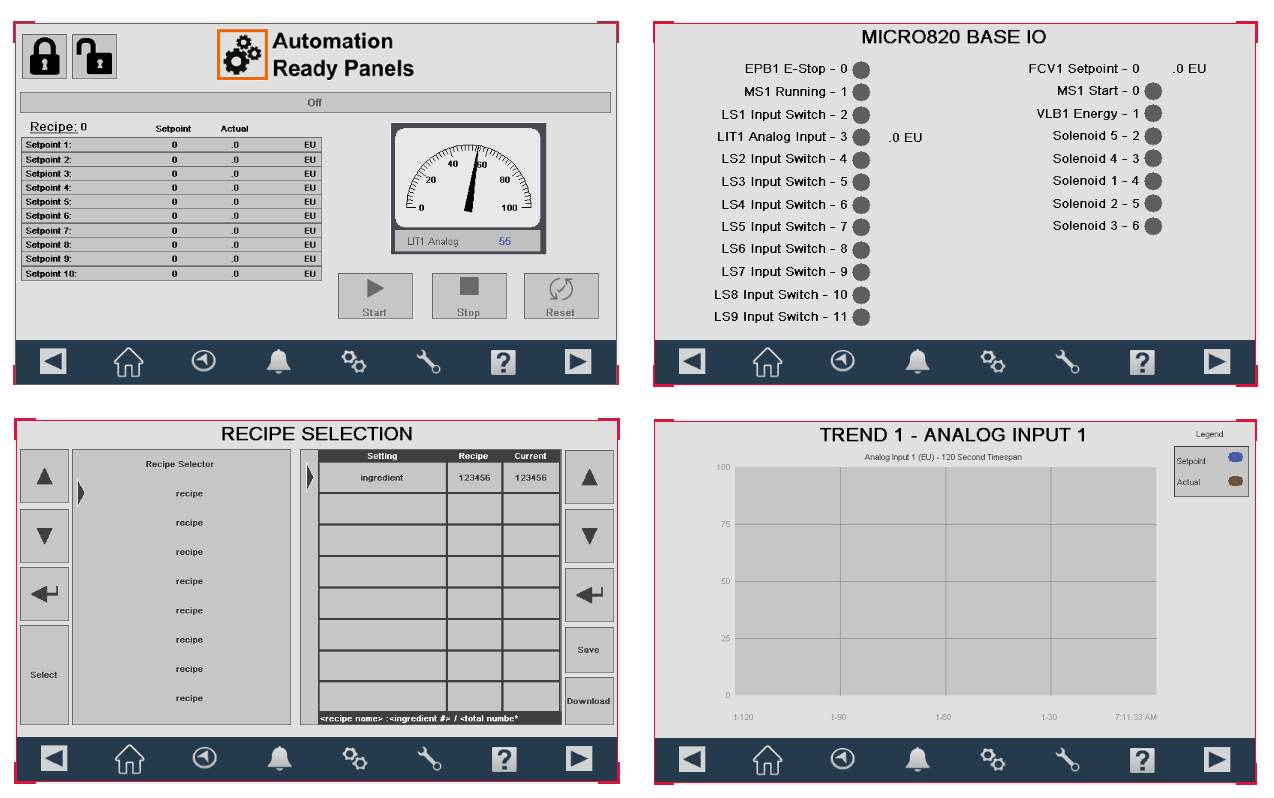

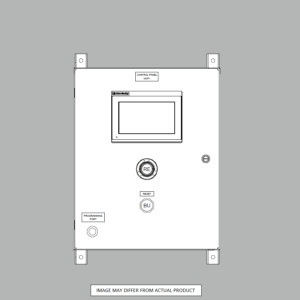

- Micro820 PLC, 4″ or 7″ Color/Touch Panelview 800 HMI with Mushroom Head E-Stop and Reset Pushbuttons or LCD Display w/Start-Stop Pushbuttons (default is Start-Stop Pushbuttons Only), and combination of 100-C Motor Starters w/ Aux Contacts or Powerflex 523 VFDs

- Control Power: 24VDC (5 Amp)

- Micro820: (Up to 12/8) 24VDC Inputs or (4) Analog (0-10VDC) Inputs, (Up to 7) Relay Outputs, (1) Analog (0-10VDC) Output, pre-wired to Terminal Blocks. UPGRADE to Micro850 if more IO is required. Micro820 comes standard with 12 Inputs/ 8 Outputs, 2 Plug-in Slots.

- Red 700S Master Safety Contactor for Enhanced Hardwired Safety Circuit

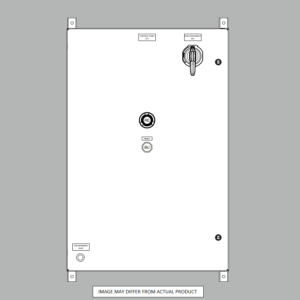

- Mild Steel ANSI Grey Type 4 Painted Panel Enclosure with Mounting Foot Kit. PANEL SIZE WILL VARY (Min. 20″x16″x8″). Fan/Filter Kit included with VFDs when required

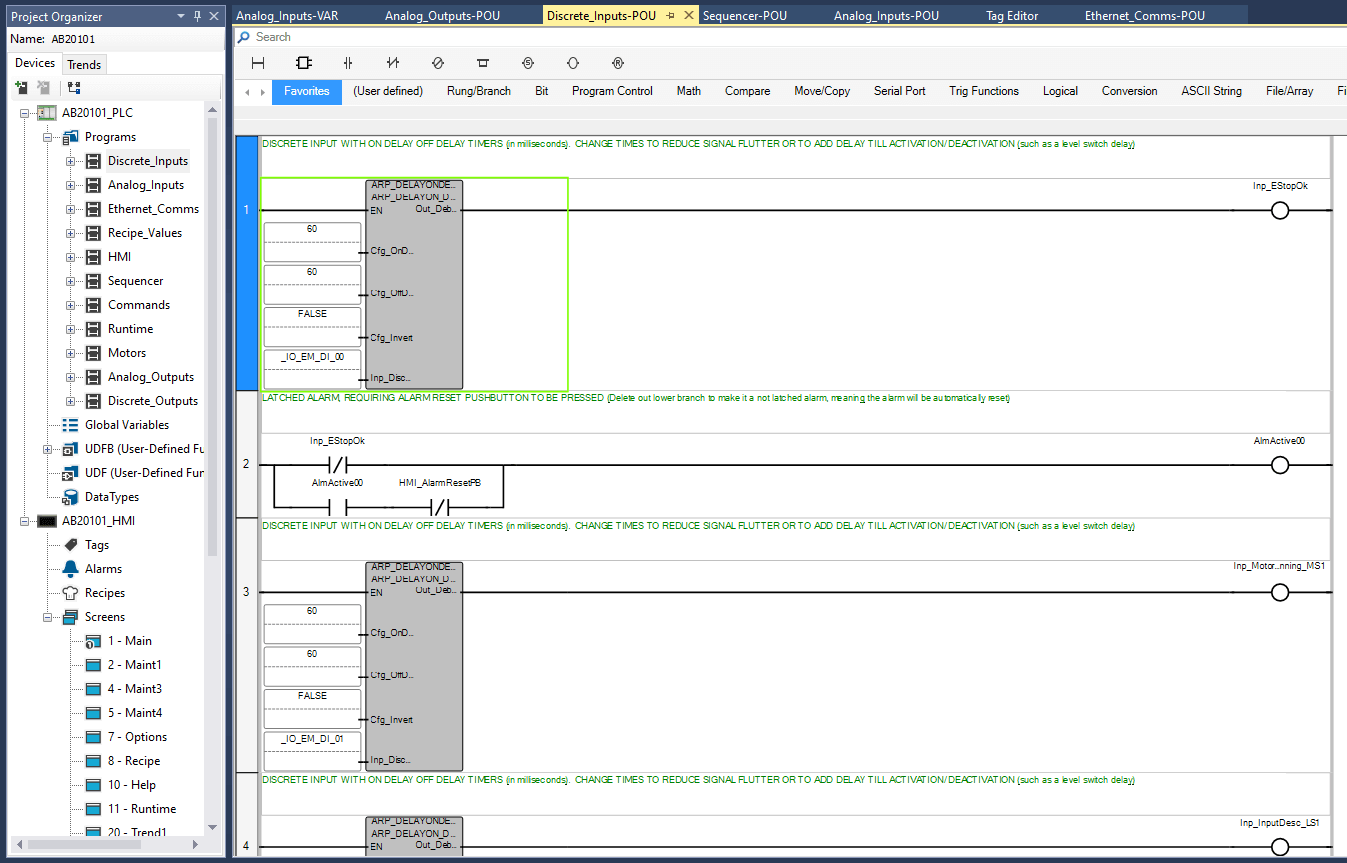

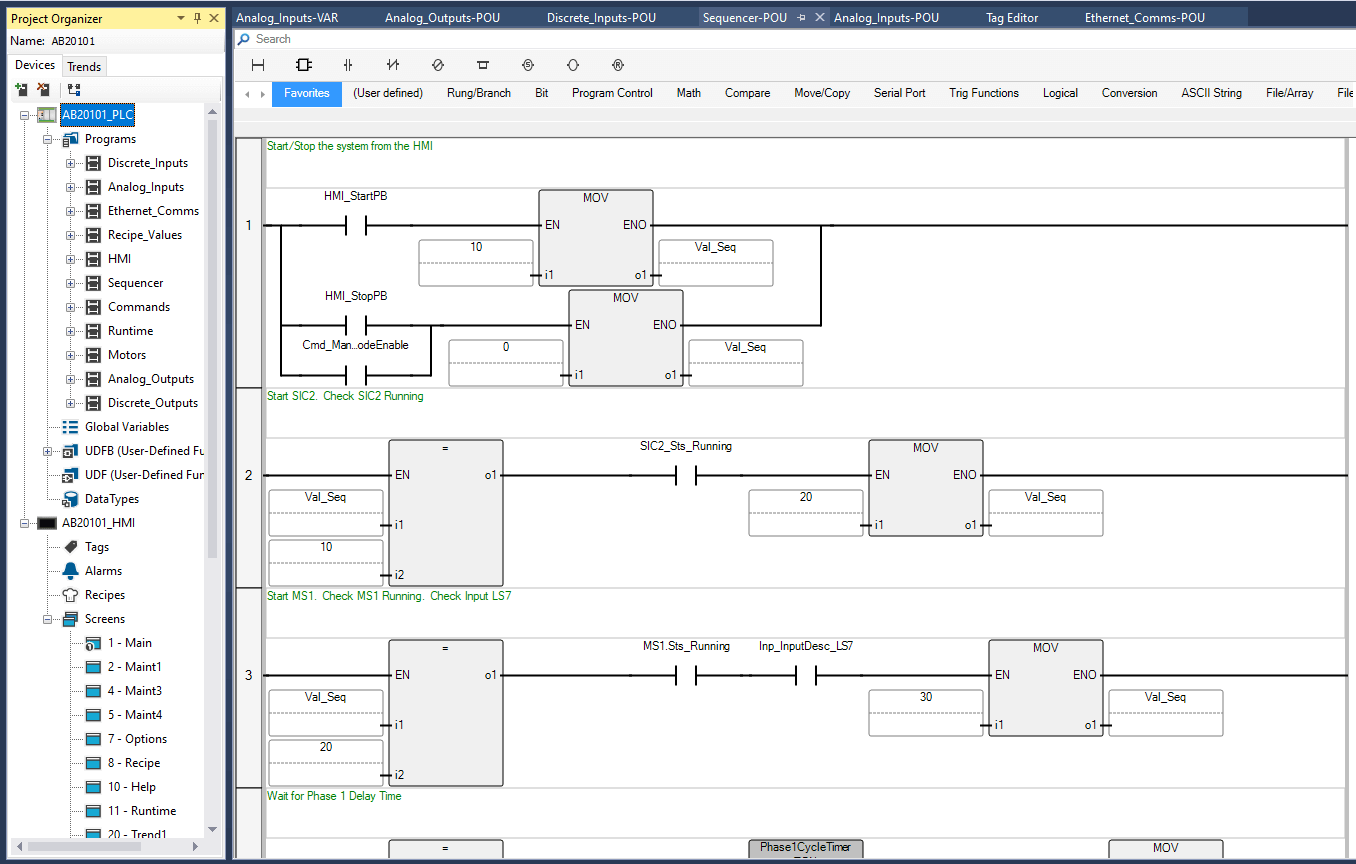

- Pre-programmed with On/Off Debounce AOIs (each input), Manual Motor Control, VFD Status, IO Status, Basic Sequencer

- Includes Electrical Schematic Drawings and User/Programming Manual

- 1 Additional Hour of Free Custom Application Programming, Drawings Updates, and/or Remote Installation Support

- Standard Lead Time: 7-10 Days (*subject to Terms and Conditions)

- Need a different version of this standard design? Please just Contact Us and we will post it for standard purchase.

- For Indoor Use ONLY. Keep out of direct sunlight

Description

Automation Ready Panels introduces the next level of the Control Panel Design Customer Experience: Hardware Design, Software Design, and Engineering Service for the price of our Competitions Hardware Build-to-Print.

This Standard Automation Panel is based around a small micro PLC, Color/Touch HMI, FVNR Motor Starters and/or Powerflex 523 Variable Frequency Drives (*). With this control panel, the PLC can be programmed flexibly with many logic options and HMI with features and settings for operational flexibility. Automation Ready Panels pre-programs this system with Discrete Input Debounce (On/Off Timers) programming blocks to keep inputs from flutter or can be used for delay timers on levels, photoeyes, or other sensors. Motor and VFD programming blocks are included with feature rich functionality. VFDs are networked over modbus to reduce IO requirements and bring in smart data from the device. A shell sequencer program has been added to reduce final integration time. The HMI has pre-designed graphics for IO status, VFD status and faults, settings input boxes, maintenance mode and manual start stop of motors, trends, user security, recipe management, and alarm summary. If desired, one of Automation Ready Panels controls engineers can program up to one hour of free programming (**) to finish off your sequencer, meeting your applications needs. This means that a fully functional controls system can be delivered and ready to install, wire sensors and motors, power up, and the system is up and running.

(*) Up to 2 Motor Starters or VFDs can be used in this design with a Full-Load Amps of less than 30 Amps (Due to our 30 Amp Max Feeder Circuit Breaker Limitation: largest motor amps x 1.25 + sum of other motor amps + non-motor continuous loads x 1.25). Visit https://www.engineeringtoolbox.com/elctrical-motor-full-load-current-d_1499.html for motor FLA chart. Panel Size may be larger than shown if large VFDs are selected (May also include fan/filter kit if VFDs are selected). Temperature calculation assumes only back of panel has no air flow, Indoor Use (out of direct sunlight), 50-90°F Ambient temperature.

(**) The free included hour of programming can also be used either partially or fully for CAD drawings updates and/or remote installation phone support.

(***) Design according to UL508a

Need a different customization to this design? Please use the Contact Us webpage to let us know how we can help.